| Jul 20, 2015

Earlier this year, international structural engineer Thornton Tomasetti released an annual report that was much more than just numbers and pats on its own back. Instead, the New York City-based firm spoke with several industry experts outside its own doors and published a series of thoughtful articles about where the AEC industry will be in 20 years. Here, we present the first of four excerpts.

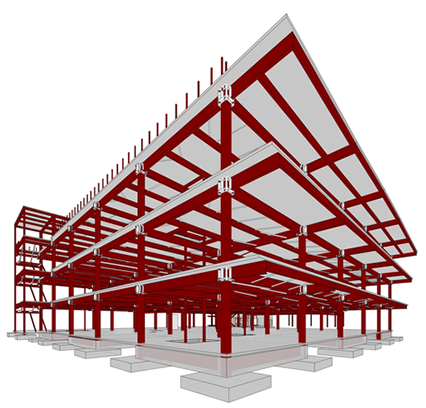

Just a decade ago, delivering a model instead of drawings was a new idea. As the practice became more common, it has changed the very shape of the built environment. The current state of model-based delivery is a snapshot of a new technology being adopted, one that could help us understand how best to integrate future technologies. We brought together a structural engineer, a steel fabricator, and two construction managers to discuss how model-based delivery has changed – and will continue to change – the way the industry works.

Here’s an excerpt of what they had to say…

P A R T I C I P A N T S

SERGE DUSSAULT, B.Sc.A., M.Eng., PE, VP, Engineering Canam Group. With more than 20 years of experience in the design, fabrication and erection of steel structures, he manages multiple design/detailing offices.

STEVEN HOFMEISTER, PE, SE, LEED AP , Managing Principal, Thornton Tomasetti. With more than 30 years experience on complex projects delivered via design-build and design-assist methods, he is a member of the firm’s board of directors and oversees its structural and construction engineering practices.

____________________________________

FRANK W. FALCIANI, MBA, LEED AP, CCM, Senior VP and General Manager, DCK Worldwide. With 40 years of experience in every facet of the construction business, he manages major construction projects with a focus on providing clients with the best return on their investment.

____________________________________

ALLAN M. PAULL, PE, Senior VP Tishman Construction, an AECOM Company. With more than 34 years of experience in the construction industry, he heads review and oversight of structural design and construction for all Tishman projects in the U.S.

____________________________________

Delivering the model has become increasingly common. What are the biggest benefits?

HOFMEISTER: Delivering a model provides a better level of information. Bidders can’t miss the complexity of the scope. It’s there. It’s very visible.

DUSSAULT: It reduces the risk of error, so the owner gets prices that are more representative of the project.

PAULL: The biggest benefits for construction are predictability of price and schedule.

HOFMEISTER: On average jobs, about 60% of shop drawings come in at least twice. On a recent project with model-based delivery, 97% of the shop drawings were accurate on the first pass. That’s a huge benefit to everybody.

FALCIANI: A complete model allows us to predict the full impact of proposed changes, to test and price them so that owners can make informed decisions.

“On a recent project with model-based delivery, 97% of the shop drawings were accurate on the first pass. That’s a huge benefit to everybody. ”

Are there any significant drawbacks?

DUSSAULT: Model delivery varies a lot from firm to firm. Right now there’s no standard.

PAULL: It has to be actively managed on our end, just like another contractor. But there are no real negatives because you’re starting the process earlier, which gives you bigger bang for the buck.

FALCIANI: There is no downside, but there are challenges. We need to update the model in real time throughout construction, but getting that to happen in the field has been a challenge. To compensate, we end up doing a lot of that work for the subcontractors because they can’t get the information in at the speed that we need it.

“We need to update the model in real time throughout construction, but getting that to happen in the field has been a challenge,” says Hofmeister. Adds Dussault,”Model delivery varies a lot from firm to firm.” (c/o Danny Bright Photo)

How will the shift to model-based delivery change the roles, relationships and responsibilities among owners, architects, engineers, fabricators and contractors?

HOFMEISTER: Delivering a model puts a greater onus on us as designers to deliver a more complete product with a higher level of information.

PAULL: I think detailing should be separated from the structural steel contractors. That information needs to be on the design side. There is still a lot of specialized engineering for the contractor to do, but it’s kind of backwards for them to be guessing what something should be, or putting in allowances or making assumptions for an estimate or a bid.

DUSSAULT: If it’s a simple job, that’s OK. But on more complex projects, the shop drawing process allows us to plan the job and to buy the material right.

HOFMEISTER: We’ve had to change the mix of our design team, to add people from the construction side who understand more of what the fabricators and erectors need us to deliver.

PAULL: It costs a lot of money to model a complex building, but it’s the right thing to do. It produces a better outcome for the clients. Fees for the designers have to go up to provide that fuller service, but I think it is money well spent, given the benefits.

“It costs a lot of money to model a complex building, but it’s the right thing to do. It produces a better outcome for the clients.”

FALCIANI: There is so much to gain. The model is a management tool throughout the construction process. It can also be used as a defensive tool to prevent cost overruns and to help challenge any claims that may arise. A model that has been updated and maintained shows the progression of construction against the schedule. It can be used to quickly develop time impact analysis to show the subcontractors, so they can rethink their position before we all start paying the lawyers.

Will more model-based delivery drive changes that lead to more alterNatives like Integrated Project Delivery (IPD)?

DUSSAULT: The details of IPD still need to become clearer, but earlier and better collaboration gets a better product, and model delivery causes a greater level of collaboration.

Virtual rendering: Shared structural image on an IPD hospital expansion job. (c/o Thornton Tomasetti)

HOFMEISTER: Success comes down to how people work together. If you read the IPD documentation, you’ll find a few basic behaviors the team must commit to. I’ve never done a “true IPD” project, but some of the very best projects of my 30-year career have had those behaviors: the teamwork, the collaboration, the open discussion of challenges and issues.

FALCIANI: There’s a huge benefit to integrating project delivery if you can get sophisticated subcontractors that are able to work with you, hand in hand.

PAULL: On a recent job with very complex geometry, the steel contractors walked through with iPads with the model on them, to understand what went where, and in what order. We didn’t ask them to do it. I thought that was remarkable.

FALCIANI: Our superintendents and engineers have their tablets with them and they’re able to literally walk through a complex project while they “walk through” the architectural vision and the engineering requirements. It’s an amazing tool.

Will 2D drawings go away completely?

PAULL: In 10 years, you won’t see any paper at all. It may be five years. Market conditions will drive it. There’s no need to spend hundreds of thousands of dollars printing drawings.

DUSSAULT: I think we’re getting close. We used to have phenomenal printing capacity in our drafting offices, but now several of them are paperless. They work from electronic information only.

HOFMEISTER: Five years ago, a job site would have a trailer devoted entirely to layout boards and racks of drawings. Now that trailer has five 84-in. monitors – smart screens so you can mark things up in Bluebeam, take snapshots and send them to people. We’re moving pretty quickly.

FALCIANI: Clients are willing to pay us for iPads, but not for blueprints.

“Clients are willing to pay us for iPads, but not for blueprints.”

Will model-based delivery change the buildings, themselves?

PAULL: You’ve already seen it. Nothing is square anymore. All the buildings twist, slope, and turn.

FALCIANI: Exactly. The sky’s the limit on the architect’s imagination; they can just turn it loose. If they can envision it, we can build it.

HOFMEISTER: With model-based delivery, we are able to envision and deliver much more complicated buildings.

DUSSAULT: In much less time. Executing that complex geometry with our current tools is not much more difficult than it was to do simpler geometry 20 years ago.

HOFMEISTER: That’s the real impact: we can digitally imagine and deliver complex schemes with no more issues and challenges than standard buildings.

Twist, slope and turn: To celebrate this summer’s 2015 Toronto Pan Am / Parapan Am Games, the province created Ontario’s Celebration Zone at Toronto’s Harbourfront Centre. Hariri Pontarini Architects, along with Thornton Tomasetti, Blackwell Structural Engineers and fabricator Tectoniks, all helped to develop the wild model.

Does concrete modeling have the same benefits as steel?

HOFMEISTER: We have the capability to model concrete, but we don’t have the partners to hand off to like we do in the steel community.

PAULL: We’re already producing concrete jobs very efficiently. A complex building would benefit.

FALCIANI: It may make sense to model some highly architectural formwork, or you may need concrete modeling in a high seismic zone. But it’s not as cost-efficient as steel modeling.

____________________________________

What will a job site look like in 20 years? Will there be people? Or will robots be following instructions from a model?

PAULL: I certainly hope not!

HOFMEISTER: We’re already seeing some industrialized construction. With repetitive buildings, automation is more likely. It’s uncomfortable to think it could all be done by robots, but 20 years ago, no one could deliver a 3D model of a building either.

iBricklayer: In 2013, Construction Robotics unveiled the semi-automated mason (SAM) that can lay up to 3,000 bricks in a day. Earlier this year, it was named ‘Most Innovative Product’ at World of Concrete.

PAULL: I see opportunity for prefabrication and pre-assembly. But I don’t see someone coming in and pushing a button that causes a team of robots to go out and build the building, not when each building is unique.

FALCIANI: Robots are not going to build one-off buildings anytime soon, but someone’s going to devise something to do the welds in the field. Or we’ll modularize more components. Owners want buildings faster, and for less money. That is going to drive the process of being innovative.

Note: This article is from the BuiltWorlds archives. Some text, links, and images may not appear or function as they did in the original post.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.