Online or in-person, all of us are consumers at the end of the day. So it has been fascinating, to say the least, to watch the rise, fall, and apparent rebirth of the retail construction market in recent years, as sophisticated mall owners and asset managers across the U.S. seek to employ new strategies to enhance customer experience in a rapidly evolving retail landscape.

Following potential shoppers from downtown Chicago to suburbia, and now back again, many property owners are finding it cost-effective to reclaim once-thriving retail properties in both urban and suburban areas and then to breathe new life into them. And contractors are using the latest technology to help them revive such spaces, often fully operational, as swiftly and as efficiently as possible.

At the Ford City Mall, just 13 miles southwest of Chicago downtown, the one-time home of a sprawling, World War II-era airplane engine manufacturing site officially became one of the world’s largest indoor shopping facilities when it opened in the summer of 1965. How big a deal? Well, some 200,000 Chicagoans attended the grand opening!

Today, owner, a NYC based REIT, and property manager Mid-America Asset Management are determined to recapture as much of that early magic as possible given extraordinary urban density in the immediate trade area of over 250k families in a 3-mile radius, by embarking on a long-desired renovation to Ford City Mall. Working with two Chicago-area firms, designer OKW Architects and general contractor Graycor Construction Company, the historic mall has remained open throughout this year as work has advanced steadily toward completion later this month.

Since January at the Ford City Mall, Graycor has teamed seamlessly with electrical, painting, and flooring subcontractors to deliver 95,000 sq ft of renovated mall common area on a fast-track schedule in a “live” environment. The work scope included new flooring finishes and light fixtures, repainted corridors and ceilings, plus new LED lighting, seating, signage, and tech workstations.

“The mall was operational the entire time, so most of the work was done after hours,” notes Jyot Parmar, Graycor senior project manager. “For flooring installation, we could have followed the existing profile of the floor with minimal floor preparation in most areas. However, based on experience with similar mall renovation projects, we decided that conducting a detailed assessment of the existing floor profile would be beneficial in identifying floor leveling requirements.”

That meant Graycor had to use laser scanning to survey the existing flooring and determine floor leveling requirements at areas of new luxury vinyl tile (LVT) in the existing corridors and thoroughfares between stores.

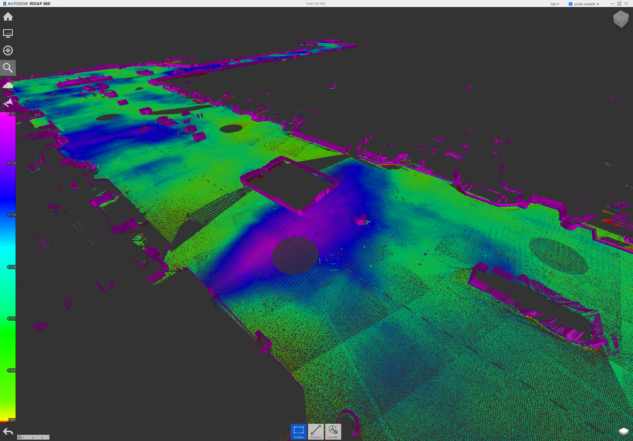

“We hired TruePoint Laser Scanning to help us with this and they used Leica P40 scanner for the job, collecting data at a rate of 1 million points/second and generating a unified point cloud (3D scan) with an accuracy range within 2 to 4 millimeters.,” recalls Courtney Lamoureux, Graycor’s virtual design and digital communications specialist for the project.

For LVT areas, the manufacturer required the floor flatness tolerance to be within 1/8” in 10 feet while the carpet areas could be more forgiving due to the thickness of the flooring material used. Autodesk Recap was used to create a longitudinal section of point cloud and after setting the appropriate limits, the team identified relatively quickly the highest and lowest spots on the floor. The information was used to assess the impact of existing conditions and potential warranty issues related to adhesion, wear pattern and aesthetic if the proposed LVT pattern was used on the current floor profile.

Although the results showed no aesthetic concern, the potential cost to overcome these warranty issues and meet the manufacturer’s floor flatness requirements in LVT areas was estimated at $120,000. By performing the laser scanning well in advance of starting the LVT scope in lieu of relying on the traditional approach used by installation crews just before installation, multiple subcontractors and LVT manufacturer collaborated to determine actual floor preparation requirements which resulted in competitive pricing and a substantial cost reduction in floor preparation to under $20,000.

“Graycor’s diligence in performing the laser scan and their early communication helped us identify and resolve a potentially costly issue in an effective and timely manner.” Noted Patricia Mahony, Vice President, Construction Management, Mid-America Asset Management. Inc.

The practice has become standard for Graycor, something not every contractor can say. “We do a lot of renovation and redevelopment work within live environments, so this has really become part of our workflow now,” notes Lamoureux. “We want the most accurate information we can get, so performing these scans as early as possible is an excellent way to ensure constructability.”

All told, the owner believes the cumulative effect of the new onsite, communal shopping experience will be able to surpass the disconnected remoteness of the lonely online consumer.

This article was sponsored by Graycor. To learn more about their construction services, click here.

This article was sponsored by Graycor. To learn more about their construction services, click here.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.