Paris Summit Preview

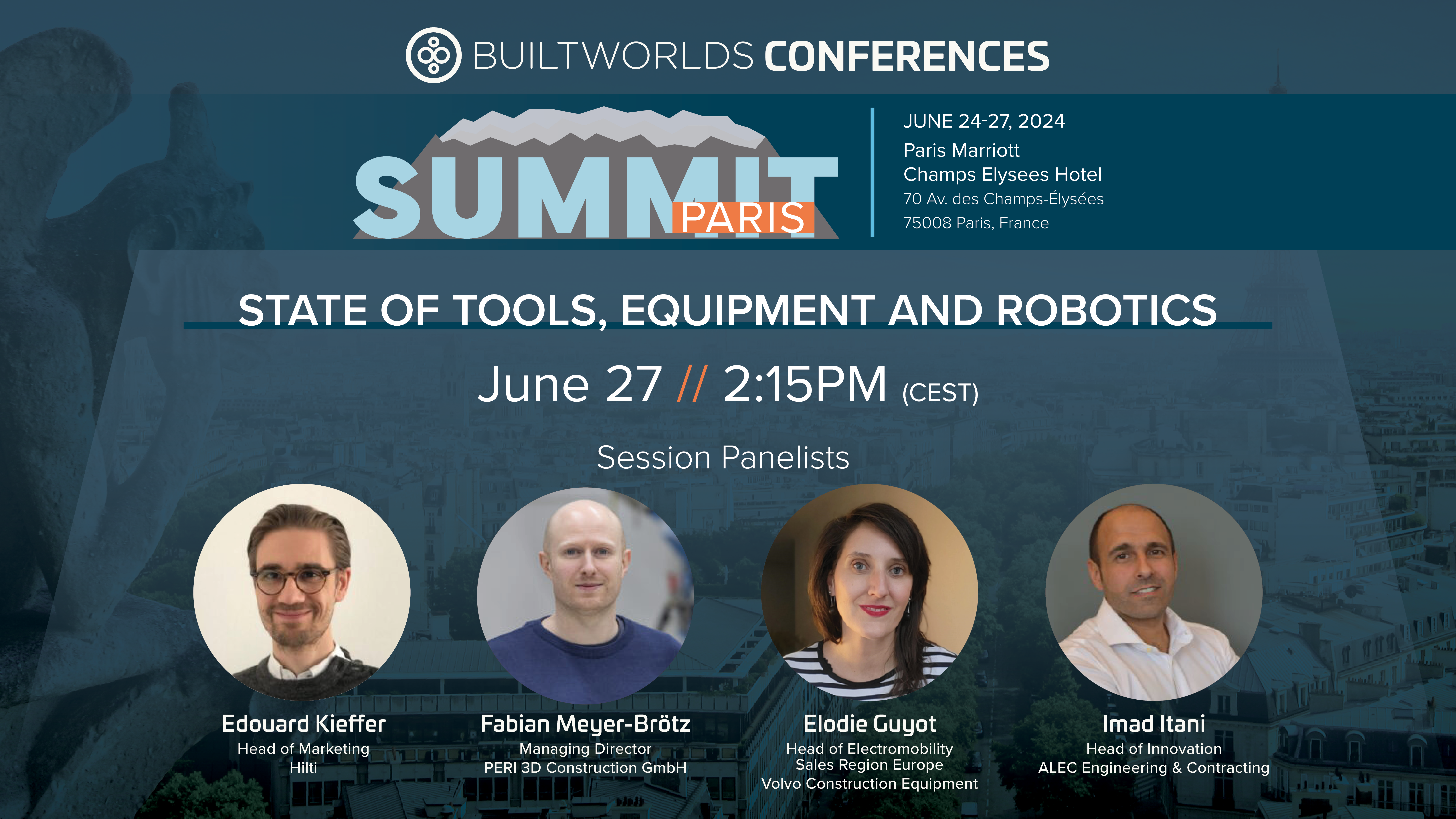

Elodie Guyot, who leads electromobility solutions for Europe at Volvo Construction Equipment, will be a panelist on the State of Tools, Equipment, and Robotics Panel at BuiltWorlds’ Paris Summit in June. In advance of the conference, we had a chance to speak with her about her career and work's focus: introducing electric machines to the market and advancing sustainable construction.

Over her 17 years at Volvo, Guyot has charted an impressive path while developing deep expertise in the field - moving from operations and product development into marketing for compact excavators, along with business development related to excavator innovation and strategy.

Although she doesn't have a technical background, her natural curiosity has served her well, Guyot says. "Each time I see something new, I'm interested in that transformation."

A moment of transformation in 2019 led Guyot to some of her most exciting work yet - Volvo's launch of the world's first compact electric excavator, ECR25 electric, a project she managed and that ultimately led to her position on the leadership team.

In her current role, Guyot is committed to advancing zero-emission job sites. The development of the ECR25 electric was a big step for Volvo, but Guyot insists the company's work doesn’t stop with one type of product or technology. While the execution of the goal is step-by-step, Guyot's team is constantly learning and willing to expand when it comes to Volvo's portfolio.

"There are plenty of different technologies," she says. "Today, it's electric; tomorrow, it can be hydrogen. This is just the beginning."

While the company forges ahead, the journey won’t be simple, she says. Guyot calls access to electricity a "bottleneck" for some customers. With that, her team is working to find solutions to remove that obstacle, which involves working with global energy providers through Volvo Energy, Volvo's business area devoted to providing batteries and charging solutions for its electric equipment.

One solution is to bring electricity to jobsites, in the form of power units or charging stations. Battery-powered solutions can be a balancing act, Guyot cautions - while they deliver towards the goal of zero emissions, they also increase the cost and weight of the machine. That's why energy sources outside of the machine itself are a key player in the development of electric machines. Batteries in Volvo CE's electric construction machines use lithium-ion technology, which allows for the charging process to be initiated at any stage, not just at an empty battery. This flexibility results in an extended working time of the machines.

"I think that some people think what the industry is doing now around electromobility, electrification and zero-emission jobsites is just a prototype. We are obviously still trying to learn and are still investigating different technologies, but many electric solutions are widely available now," Guyot says.

Beyond her work at Volvo, Guyot acknowledges that it may be complicated for people to understand what is going on with developments related to electromobility and fuel alternatives within the industry. Many advancements have been made across numerous companies, and while it is early, it is still creating a broad impact, she says.

"Where we are now in this journey, we need to think about the whole ecosystem."

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.