On its face, the term “data-driven design” might suggest an impersonal, robotic process that inhibits human creativity and replaces it with cold, unfeeling mathematics.

On its face, the term “data-driven design” might suggest an impersonal, robotic process that inhibits human creativity and replaces it with cold, unfeeling mathematics.

In practice, however, the exact opposite may be the case.

Indeed, most AEC practitioners ultimately would say that providing owners and end-users with built assets that meet their needs is truly the goal of any project. And today’s ongoing data revolution, fueled by the ever-expanding internet of things (IoT), already is making that goal more achievable.

At least that was the case made last week at the latest installment of BuiltWorlds’ #BuildIdeas Breakfast Series, this month focused on “Data Driven Design”. The two headline speakers were Rob Risany, worldwide innovation executive for IBM Watson IoT, and architect Ron Henry, SVP and chief facilities management, engineering and construction officer for Michigan’s Detroit Medical Center. We recorded video interviews with both gentlemen that will be released in the weeks to come, but for now, here are five takeaways (and two videos) that give you a feel for the data-driven revolution all around us…

1. Enabling machines to talk to us about their own performance and maintenance.

“Artificial intelligence (AI) is critical,” said IBM Watson’s Risany. “If I can ask Siri for directions, why can’t I walk up to a bulldozer and ask it how much life it has left on its treads?”

2. Owners now can collect data that enables them to tailor products specific to customers.

“[Elevator giant] KONE came to us, because they felt they needed to do a better job of maintaining their field assets,” added Risany. “But we soon realized that we were also talking about captive eyeballs on folks riding the elevators. Just from which buttons they pushed, we would know where they were going, and who they were seeing in the building. So, why can’t we tailor advertising to them?”

- Below, see KONE’s take on the experience of getting smarter about their users…

3. The more stakeholders involved early on in a project, the leaner its completion can be.

For the new Detroit Mercy Children’s Hospital, “We had $200 million to build 300,000 sf of new space,” recalled Henry. “We realized that the more we could do up front, the better it would be. So we employed ‘integrated facility design’.”

4. Commitment to broad inclusion must be sustained to be effective and responsive to client needs.

“I have been a healthcare architect for 25 years, but I don’t know the healthcare process,” conceded Henry. “So, with ‘Integrated Facility Design’, we enlisted as many stake-holders as we could up front to make the design work for them. That meant we talked to patients, nurses, doctors, janitors, administrators, as well as architects, engineers, subcontractors, and more. All met regularly to provide data we could use in the design.”

5. Even today, a tangible 3D project model can still work better than a virtual computer model.

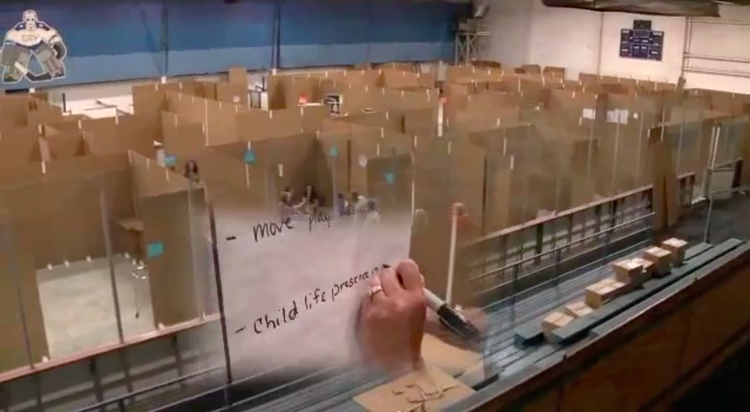

“From May to October 2014, on an ice rink, we built a full-scale cardboard model that we called our ‘Cardboard City,'” recalled Henry. “They said we were crazy, and even I was skeptical. But it worked.”

- Below, the Cardboard City on Ice, plus a short video feature from a local Detroit TV station…

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.