August 2021 Analyst Call Recording: Modularization & Prefabrication

Modularization & Prefabrication On this edition of BuiltWorlds Modularization and Pre-Fabrication Calls we met with Sam Tikriti, Volumetric Building Companies’ chief operating officer to discuss the state of modularization generally and also the story behind his firms’ recent acquisition of Katerra’s state-of-the art facility in Tracy, CA. Sam brings over […]

Bottom-Up Transformation: How To “Do” Innovation In Construction

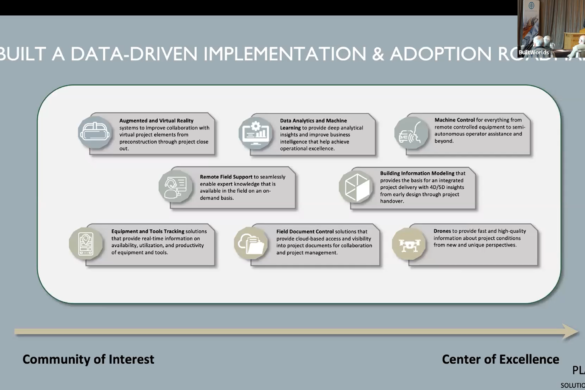

In this session, Nate Fuller, Managing Director of Placer Solutions, discusses what large organizations can do right and how to accelerate existing efforts in order to deliver lasting change through field change agents.

BuiltWorlds Venture Forum Demo Drop – Buildots

Buildots turns construction sites into digitally managed manufacturing environments. AI-technology analyses video captured by 360-degree hard hat mounted cameras, together with BIM and schedule data, to detect the exact status of every activity on the construction sites. Using Buildots control centre app, data is easily accessible for supporting the project’s […]

Future Workforce (Construction Productivity) | Analyst Call

Discover how the industry measures productivity, what measure might be most appropriate for construction and how emerging technology influences that discussion.

Smart Tools – Delivering Connectivity for Oracle’s Innovation Lab

In this session, Frank Malangone, Sr. Director of Product and Industry Strategy at Oracle, and Andy Lambert, Group Program Manager at Milwaukee Tool, discuss the development of Oracle’s Construction Innovation Lab in Deerfield, IL with the help of Milwaukee Tool’s smart tool lineup, powered by One-Key.

BuiltWorlds Venture Forum Demo Drop – Ynomia

Ynomia’s mission is connect the “things” in construction to amplify human potential. Ynomia’s connected sensor network transforms the traditional construction processes, giving builders the ability to harness real-time data to build faster and safer.