On the heels of the 2024 Paris Summit—which took place at nine unique venues over the course of four days and played host to over 80 forward-thinking companies, with 20 countries represented—we look back at our tour of the La Fabrique du Métro, an exposition of the impressive work that has been done and is being done (in concert with VINCI Construction and VINCI Energies) to add to and extend the city’s existing metro system, called the Grand Paris Express.

On the heels of the 2024 Paris Summit—which took place at nine unique venues over the course of four days and played host to over 80 forward-thinking companies, with 20 countries represented—we look back at our tour of the La Fabrique du Métro, an exposition of the impressive work that has been done and is being done (in concert with VINCI Construction and VINCI Energies) to add to and extend the city’s existing metro system, called the Grand Paris Express.

The Grand Paris Express is one of Europe’s largest infrastructure projects. It aims to transform the transportation landscape of the Greater Paris Metropolis by connecting its suburbs without passing through Paris, significantly reducing travel times. Once complete, an estimated three million passengers will use the metro daily.

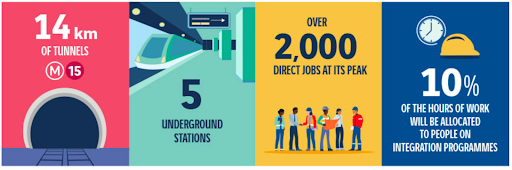

The staggering €2.5 billion project involves extending an existing metro line (metro 14) and building four new metro lines in the inner and outer suburbs (metros 15, 16, 17, and 18). The Grand Paris Express will enter service in stages between 2024 and 2030. BuiltWorlds member VINCI Construction won the first design-build contract in 2023, worth €2.71 billion, and will work until 2031 covering the section of line 15 west.

VINCI Construction: Pioneering the Grand Paris Express Metro Extension

VINCI Construction is playing a pivotal role in this extensive metro extension project, which will add over 200 kilometers of new track and feature 68 new stations. In addition to promoting accessibility, this project is set to revolutionize urban mobility, reduce congestion, and promote sustainable development in Paris and Europe more broadly.

Innovative Processes and Technologies

- Tunnel Boring Machines (TBMs) and Vertical Shaft Sinking Machines (VSMs)

VINCI Construction uses advanced tunnel boring machines (TBMs) to excavate the vast network of tunnels required for the Grand Paris Express. These state-of-the-art machines— which cost upward of €15 million and are only fabricated by two companies globally—are designed to efficiently and safely bore through the diverse geological conditions found in the Paris region. Each TBM is equipped with technology that allows for precise navigation and real-time monitoring, ensuring the accuracy and stability of the tunnel construction process.

The tunnel boring machines digging line 14 south and line 15 south in the Grand Paris Express program have crossed paths. Photo Credit: VINCI Construction. In addition to leveraging TBMs, VINCI is also using vertical shaft sinking machines (VSMs) that are installed at the same time as precast concrete segments and provide structural support, saving space above ground. This technology proves highly useful in built-up urban environments, which is especially pertinent considering 90% of the project is underground and intentionally designed with comfort in mind to not disturb residents.

- Building Information Modeling (BIM)

The implementation of Building Information Modeling (BIM) is a cornerstone of VINCI Construction’s approach to the Grand Paris Express project. BIM facilitates the creation of detailed 3D models that integrate various aspects of the construction process, from design and planning to execution and maintenance. This digital framework enhances collaboration among all stakeholders, streamlines project management, and reduces the risk of errors and delays. Their BIM software includes a database enabling stakeholders to access project data in real-time from desktop or mobile devices, providing a tool to forecast events and optimize things like construction costs and project duration. - Sustainable Construction Practices

An exhibit of concrete with steel fibers at La Fabrique du Métro. VINCI Construction has demonstrated a commitment to sustainability in the Grand Paris Express project. The company employs environmentally friendly construction methods, such as using low-carbon concrete and recycled materials. One such example is their implementation of recycled concrete—which uses steel fibers as opposed to rebar, saving on both concrete and steel.

VINCI has also designed, endorsed, and marketed a range of Exegy low-carbon concretes, in partnership with Ecocem, that repurposes waste products from the steel industry. The use of innovative materials enables VINCI to reduce its emissions by up to 60% compared to traditional concretes, while maintaining performance.

- Smart Station Design

The new stations being constructed as part of the Grand Paris Express are designed with cutting-edge technology to enhance passenger experience and operational efficiency. Beyond operating as a showroom, La Fabrique du Métro serves as an R&D center of sorts to test various designs before implementation. Impressively, the new stations will be 100% accessible for people with limited ability, a stark contrast to the 3% that is currently accessible. These modern stations are also built to be energy-efficient, incorporating renewable energy sources and sustainable design principles.

For more on the latest trends, innovation, and technology emerging for infrastructure projects, join us on October 1-2 in Washington, DC, for BuiltWorlds’ annual Infrastructure Conference. Example topics include site feasibility and work technology, AI and its impact on infrastructure project design, sustainability and decarbonization, project management in infrastructure, the future of water, waste, transportation, and the role of robotics, drones and other advanced equipment in infrastructure. Reach out to research@builtworlds.com with questions.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.