Featuring:

Project Details

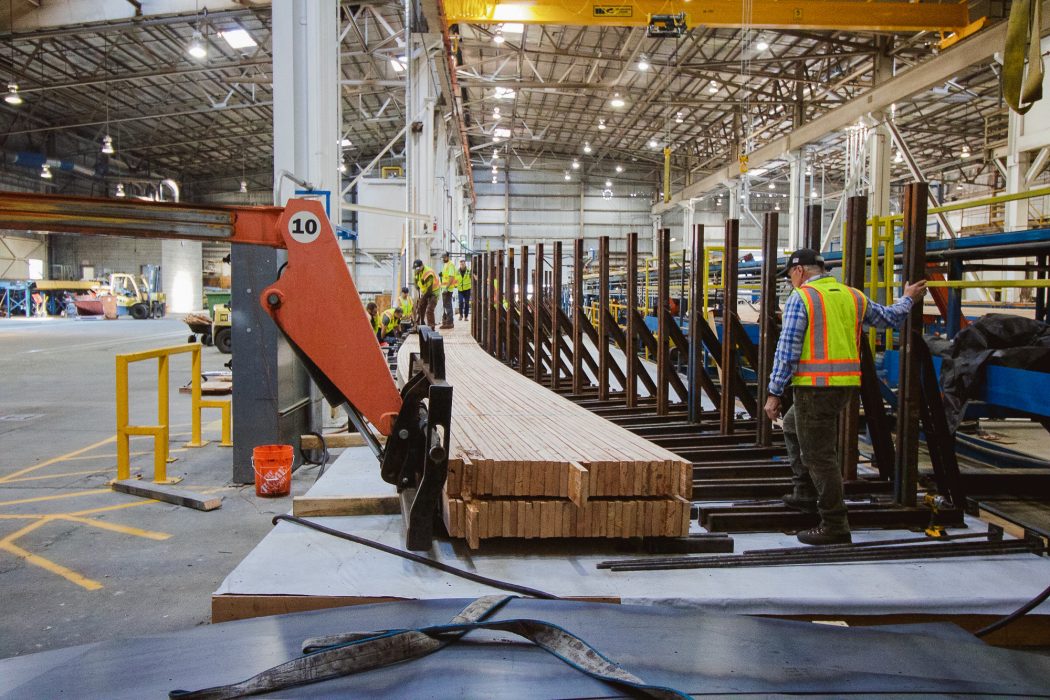

The centerpiece of the Portland International Airport (PDX) Terminal Core Redevelopment is a stunning, 400,000 square-foot timber roof that pays homage to Oregon's rich natural beauty while also highlighting its growing wood innovation sector, providing travelers with a deep connection to the forests of the Pacific Northwest.

Objectives

Timberlab came onto the project in 2019 in a design-assist role to ensure the design of the mass timber roof structure could be manufactured and procured from regional timber manufacturers—sustainably and cost-effectively.

Outcomes

To avoid disruption to the traveling public, the new roof is being built a half-mile away from the current airport roof, then disassembled in 100x300 modules and assembled above the existing roof in segments over a one-year period.

- Comprised of approximately 3.3 million board feet of Douglas Fir

- The roof features over 400 80-foot glulam arches

- Materials were procured from a diverse array of local landowners and Pacific Northwest tribes across the region within a 600-mile radius

- Hyla Woods, Skokomish Tribe, Anne and Richard Hanshcu, and the Nature Conservancy provided the Douglas Fir material for the lattice

- The roof features a Mass Plywood Panel roof diaphragm and skylight curbs, and a lattice of 3x6 Douglas Fir inspired by regional weaving traditions traced back to four forest landowners in the region

Next Steps & Future Use

N/A

BuiltWorlds Analysis

Mass timber and other types of engineered wood are increasingly being specified globally due to their environmental benefits, strength, and versatility. These materials, often sourced sustainably as seen in the Timberlab case study above, sequester carbon and have a lower environmental impact than traditional concrete and steel. Additionally, using prefabricated timber components accelerates construction, reduces waste, and enhances precision, making it an attractive option for modern, sustainable design and construction.

In fact, data from BuiltWorlds' 2024 High-Performance Materials Tech Specialty Report reveals that nearly 50% of respondents utilize or specify high-performance wood solutions in some capacity for their projects.