The construction industry is facing a massive and growing labor shortage. Despite rising interest rates and a downturn in the commercial real estate industry, the bureau of labor statistics reported job openings in the sector remaining stubbornly in the 500,000 range, 441,000, exactly. As the industry struggles to add employees to meet still growing demand, wages are rising faster than inflation. The industry’s most common approach to addressing its skills shortage is more training and more recruiting efforts. However, one construction industry startup, founded by construction equipment industry veterans, is pushing for much better, autonomous and easier to use construction equipment as the way to “do more with less.”

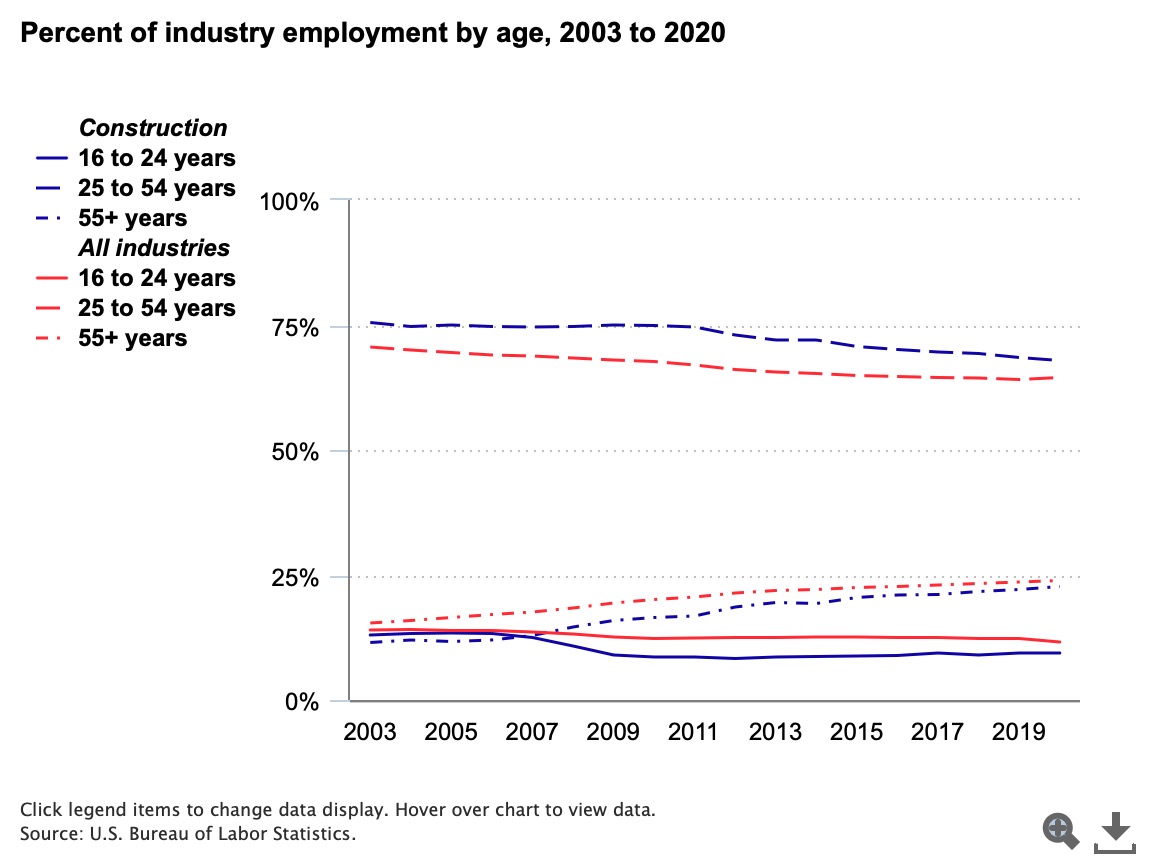

While the industry is already in the midst of a labor shortage, things look likely to get a lot worse, demand continues to increase and labor supply decreases. On the one hand, policy makers around the world are advancing agendas that seem to support projections of increasing demand for construction well into the future. In the US, billions have been allocated to new manufacturing and infrastructure spending, and the Biden Administration has advanced a goal of 2 million new or renovated housing units to compensate for a deficit in development over the past decade and to help combat an increasing lack of affordability in housing. At the same time, the existing construction labor pool is continuing to age more quickly than the rest of the country’s labor pool. Based on labor department statistics, it seems likely that the industry in the US could lose about 2 million of its most highly skilled workforce over the next decade.

While more and better training opportunities would certainly represent one way to help ease the industry’s problems, another answer could be to introduce construction equipment that reduces the amount of labor needed to perform tasks, lowers the skills required and creates job opportunities within the industry that are cleaner, safer and less physically demanding. While traditional industry equipment manufacturers have been slow to promote the commercialization of remotely operated and autonomous construction equipment, a new generation of startup entrepreneurs, many with backgrounds at traditional equipment companies, are forging new partnerships and starting new companies to fill the gap.

Two such entrepreneurs launching a new equipment solution for the construction industry are Henri (Myounghan) Lee, CEO and founder, and Jae Choi, Chief Operating Officer, of Xpanner, a South Korean autonomous construction equipment startup, founded in 2020. Having held strategic positions in technology at global construction equipment manufacturer Doosan, Lee and Choi are veterans of the sector with an understanding of the sector’s construction equipment industry, the relevant technology, and also with experience working and studying in Asia, Europe and the United States.

Xpanner has obtained the investment backing of heavy hitters like Korean Investment Partners, the largest investment fund in South Korea and KB Investment, a Seoul-based VC firm. They also have global technology partners in Finnish construction automation firm Infrakit and German mobile automation company MOBA. Xpanner established its North American subsidiary in November 2022, and has forged partnerships in North America with Canadian-based telematics leader Geotab and San Francisco-based DroneDeploy. With these partnerships, Xpanner is seeking to create solutions that will both automate and simplify construction projects.

Xpanner is one of a number of companies in construction less focused on developing entirely new robotics for the industry, and more focused on helping the industry modify existing equipment to allow it to work more autonomously, remotely and efficiently. At our recent Venture West Conference, Lee and Choi demonstrated how their modified construction equipment is able to allow solar field builders to perform installation work, normally requiring two more experienced workers, with only one less experienced worker.

Installing solar panel structures autonomously is only one use case. Xpanner looks to bring its mix of autonomous and remote operations solutions to various applications on the jobsite, performing and increasing variety of tasks.

It is still early in the effort to automate construction equipment. However, Xpanner and its global network of partners, shows clear progress in the sector.

Beyond firms like Xpanner are those like FBR which recently announced a partnership with major, global materials company CRH and is automating the field of brick laying, as well as new robotics equipment companies like Jaibot, Canvas and Kewazoo. Taken together, they represent an increasingly serious world of new and more advanced equipment solutions for the industry which promise to change the landscape for those working on job sites in the future and possibly also help to solve the industry’s labor shortage.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.