by MIKE HRYMAK and ROB McMANAMY | June 11, 2015

Subcontractors admittedly are on the front lines of any and every construction project. So, as our industry continues to be disrupted by the ongoing surge in tech use among designers and builders, alike, it’s no wonder that specialty trades across the board are equally determined to keep up with all their potential project partners.

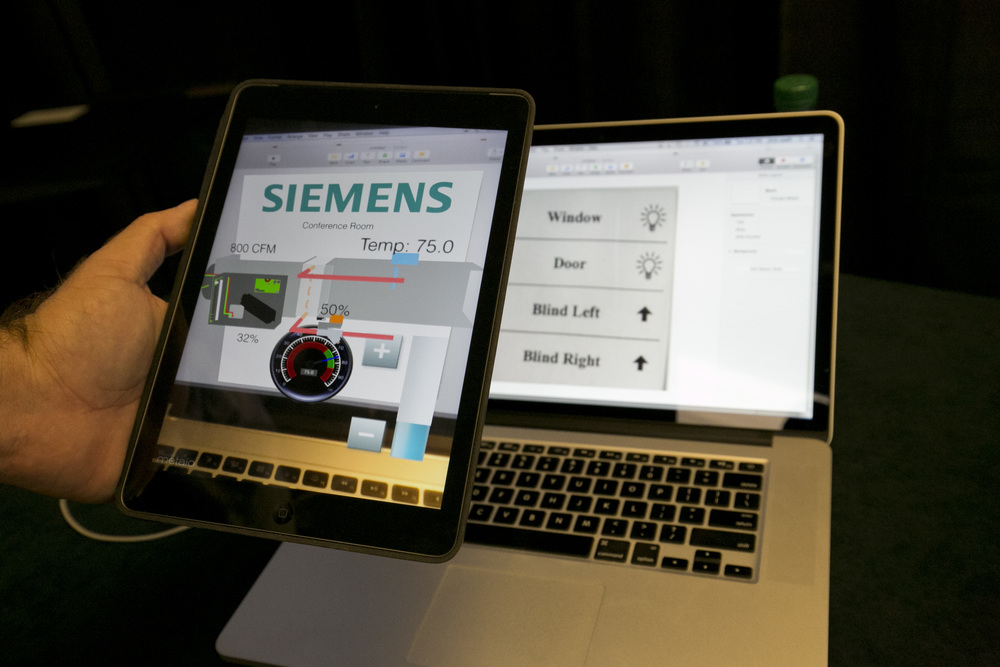

With that in mind, the latest in current technology and what’s ahead were the focus of the first-ever Mechanical Contractors Association of America Construction Technology Conference, held this week at “Hamburger University”, on the suburban Chicago campus of McDonald’s Corp. More than 200 MCAA members from across the U.S. attended the one-day program to hear from industry experts and see demonstrations by vendors from Autodesk, Trimble, Leica Geosystems, Penta Technologies, Siemens, Johnson Controls, SysQue, XOEye Technologies, Bridgit and Cubicle Ninjas.

“I think we had a good mix here of some very tech-savvy members, as well decision-makers from other firms who are ready to make a greater investment,” said MC Brian Helm, MCAA Education Committee Chair, and President & CEO of member Helm Group Inc., Freeport IL.

Commented one attendee, “We actually jumped in too deep 10 years ago. We invested in technology that was not compatible with what others were using, and it ended up just sitting on our shelf. So we are trying to be more selective now.”

“drinking data From a fire hose”

In the auditorium, speakers included MCAA Tech Committee advisor Paul Doherty, AIA, President & CEO of The Digit Group, Colliersville TN. Presenting on “The Rise of the Super Sub”, he urged the group to get out in front of their competitors and to take the lead on projects. An international expert in “Smart Cities”, Doherty told attendees that technology such as iBeacons and all manner of innovative monitoring devices were collecting “big data” about mechanical issues such as water usage, leaks and system blockages, etc. “We basically have a situation now where the toilet can ‘talk’ to the sink or the shower head,” he said, adding with a smile. “Heaven help us if they decide to stop talking to each other!”

Such innovations are like ingredients, he explained. They come together now in a recipe for a project or a building, creating smart cuisine for a smart city. “So, not only will we have the bathroom talking to the kitchen, we’ll have entire buildings talking to each,” added Doherty. “By 2050, China says it will build 500 smart cities.”

Picking up on that theme, Jeff McClain, director of U.S. buildings operations at global sub Schneider Electric, later spoke on smart buildings in his presentation “Beyond Energy”. Attendees would do well to note that Johnson Controls and Siemens were both sponsors of the event, he told the group. “Think about why they are here,” said McLain. “So, if you don’t have experience managing your data on projects, I strongly encourage you to partner with someone who does. There is a huge opportunity now if you understand the opportunities that all this data presents.”

And the flood of data is influencing every aspect of the business now. “All this dimensional data is moving into our fabrication shops,” noted Rick Dustin, VP of Engineering for Atlanta-based McKenney’s Inc., where he manages mechanical design and drafting. “These data loops naturally feed into Lean Construction, in that when you find errors, you can remove them from the process in real time. So, as a result, our guys in the field are constantly finding ways to do things better.”

Tech Toys ‘R Us

Among presentations on 3D Printing, 3D Laser Scanning, and high-tech tool tracking, BuiltWorlds cofounder Matt Abeles moderated a “Tech Toy Test Drive” panel, featuring individual presentations from Lauren Hasegawa, of Bridgit, Kevin Carr of MasterGraphics, Aaron Salow of XOEye, and Josh Farkas of Cubicle Ninjas. Noting the accelerated pace of change already in the marketplace, Hasegawa pointed out how attendees had best pay attention because “it will only get faster from here,” she said.

One emerging technology is immersive eyewear, like Google Glass and Microsoft HoloLens. Aaron Salow explained how such tech can allow two individuals on opposite sides of the world to collaborate on solving a problem. For example, he said, an experienced technician in Detroit can train an inexperienced tech in Israel, by walking him or her, step by step, through the process of fixing the machine. “They can sit behind a desk here and give that 22 year-old on the other side of the world exactly the information that he needs,” added Salow.

Virtual reality (VR) and augmented reality (AR) are two more evolving tools of which attendees should be aware, said Farkas, adding that they “have that gut-punch impact” to immediately turn something complex into something totally understandable. As a result, “we can now walk into buildings before they are even built,” he explained.

Earlier, H.T. Lyon’s Adam Cartwright and Tim Bodor discussed how they use 3D laser scanners that turn 360 degrees to create a detailed map of an area. “Twenty minutes of laser scanning equals about five to six hours of work that two guys could get you… and they still wouldn’t have that level of detail,” claimed Bodor, noting that there is one drawback. “A laser scanner is not an X-ray machine; it cannot see through walls.”

Still, future development of handheld and drone scanners should limit that problem, he said.

In the past, the AEC industry was “communicating 3D intentions with 2D tools,” noted Hasegawa. “[But] what seems like a stretch of the imagination today may well be reality tomorrow.”

Indeed, a fitting coda applicable to so much of what was jammed into one informative day.

For more on the conference, the speakers, the sessions, and the sponsors, click here

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.