Amr Raafat is the Chief Innovation Officer at Windover Construction, a leading full-service construction management firm based in Beverly, Massachusetts, and a pioneer of innovation in the industry, with over 20 years of experience across architecture, engineering, and construction. His work and leadership has garnered recognition throughout the industry, including being named both Autodesk’s 2019 Innovator of the Year as well as its 2024 Construction Champion. Raafat is a thought leader, a podcast host, holds a master’s degree in architecture, and in February 2025 he’ll be speaking at BuiltWorlds’ highly anticipated AI/ML Conference in Atlanta, Ga.

In the lead up to the conference, we sat down with Raafat to learn a little bit more about his background, his work, and innovation in the industry.

Responses have been edited for clarity

To start, could you please share some information on yourself and your background.

I had the privilege of starting my career by working with and learning from the world-renowned aquarium architect Peter Chermayeff, FAIA, in Boston. I worked on the programming, conceptual design, and BIM management of many international aquarium projects, including the National Aquarium Expansion in Baltimore, Maryland; and the expansion of Nausicaä Centre National de la Mer in France. In so doing, I developed a deeper understanding of coordinating complex building components, which inspired me to explore the world of making big ideas and challenging designs areality through problem-solving and innovative solutions. That is how I got to construction. I received my master’s degree in architecture from Boston Architectural College.

And what are you doing now in the construction industry?

I am leading Windover’s VDC team and the IDEA™ platform to provide innovative solutions throughout the lifecycle for construction projects as well as innovative solutions for global project solutions. My role is to envision, promote and lead innovation and advancement across all company segments.

Tell me more about the work you and your team are doing.

In addition to supporting our Windover construction projects throughout the life cycle of construction, from preconstruction to handover, with digital twins, BIM MEP coordination, construability review, Drone and Laser scans, 4D planning and Mixed Reality. Windover also has a national and global footprint with innovation with our IDEA Platform. We collaborate and support architects, engineers and owners with innovative technologies such as reality capture, drone and laser scans, digital twins, BIM automation, and other advanced technologies to help with projects even before construction. We have been supporting projects with innovative solutions around North America, Australia and UAE.

For example, we worked with a company in Melbourne specializing in prefab. Their approach is remarkable, they had a challenge that their 3D models weren’t compatible with their manufacturing machines. We helped them solve that issue with digital prefab software assistance.

Windover has done some great work with Autodesk in the past, could you please share some insight on that collaboration with me?

We have been residents at Autodesk Technology Center in Boston for more than 6 years now. I consider the space a hub for innovation, where we explored applying the future solutions in construction and prefab such as additive manufacturing and robotics to increase efficiencies on our jobsites, we also built some great collaboration with robotics and software developers and mixed reality developers based in Australia. As well as Machinery manufactures such as Howick of New Zealand, One of the effective ways we push our industry forward is through cross-industry innovations. Applying working solutions from other industries to tackle the AEC space challenges.

Windover is also a very early implementor of Autodesk’s digital twin solution, Tandem. A comprehensive one-stop ecosystem that is solving the gap between construction handover and facilities operations, we have done digital twin for multiple projects including our Philips Exeter academy new dorm and multiple buildings Endicott College campus. During the last 15 years, Windover worked on more than 25 design build projects at Endicott College to hand over a web-based digital twin with all O&M manual data as well as IOT sensors for real-time tracking of building performance., we are honored for the trust the college has for Windover to bring their campus vision to life.

We are also currently building a digital twin model for our recent project at Eaton Hall Windover also was a very early implementer of the Autodesk Takeoff, a technology that is designed to streamline quantity takeoff with model-based estimation. Currently, we’re collaborating with Autodesk on leveraging robotics and digital

prefabrication on historic preservation projects and exciting ML and AI and generative design projects.

You’ve recently done some interesting work in the UAE, can you please provide some more details on that project?

Two years ago, a UAE municipality reached out to Windover to help streamline permitting drawings review and increase efficiencies in the municipal workflow. Windover has been thought after for leading-edge expertise in BIM and innovative solutions for the AEC space. At Windover, we always start by understanding the client’s challenges and processes, then we respond by developing tailored tech-first approach to tackle the challenge.

Windover combined generative AI and generative to design develop a one-stop municipal ecosystem platform called AI-enabled Automated Plan Review System (BIM-AI) (Patent-Pending). The platform recently launched in UAE automates modeling 2D drawings drawing into a 3D model, including architectural, structural and mechanical to LOD 300with necessary details for code compliance checks. Then the system checks for code compliance issues within the submission in minutes. To further streamline the process, we developed an AI-powered tool called CAD verify that allows architects to upload their drawings and instantly identify any issues, ensuring compliance with the CAD/BIM standards before submission. It’s all about automation and enhancing municipal workflow efficiencies.

How did Windover get involved in that UAE project in the first place?

Windover’s globally recognized work in construction technology and our successful work with a Dubai-based developer, where we successfully developed BIM-based cut-and-fill analysis for a large mega project development. These were the reasons for how we were awarded the project. We have been approached with the challenges, and we applied innovative technologies to address them not just for the sake of using cutting-edge tools, but to solve real challenges. It’s a great collaboration with a great client who embraces new ideas and innovations. The project was recently unveiled at GITEX Dubai, a global convention for technology in October.

What’s fascinating about this solution is its versatility. When we presented it in UAE, architects there saw even more potential uses for the resulting 3D models from the permitting workflow process. Beyond compliance checking, these models can be utilized for VR simulations, constructability reviews, and coordination. The process doesn’t just stop verification; it creates tangible, long-term value by delivering an LOD 300 models that seamlessly integrates into the project workflows. The return on investment extends far beyond initial expectations.

We have interest right now from other municipalities to implement Windover’s AI-Enabled BIM-APRS platform to streamline municipalities workflow and increase efficiency for permitting review. It’s a universal solution that can be tailored to local municipal regulations and workflows.

Please tell me some more about your projects closer to home, particularly your work with smart campuses in the Boston area.

One of the most innovative things we’ve done recently is building a smart campus with digital twins. Over the years, we’ve worked on numerous academic buildings, including projects at some of the most prestigious academic institutions in New England. At Endicott, for several projects we leveraged BIM coordination, laser scans and drones to build it better. We took things a step further by integrating digital twin technology into the campus infrastructure.

Traditionally, after completing a project, we’d hand over a massive manual or large pdf containing all the operational and maintenance (O&M) information. Facility managers would then need to go through it to find details about equipment maintenance or replacements. A few years ago, the process evolved to include QR codes that could provide quick access to information. But we went even further.

Using the fully coordinated MEP and Architectural 3D model, we embedded all the equipment catalogs and O&M data directly into the digital twin. This means that facility managers no longer need to search through physical or digital files. They can easily with minimal training navigate a web-based model, click on an element, and instantly access comprehensive information such as installation dates, manufacturer details, serial numbers, 24-hour contacts, and much more.

We didn’t stop there. We integrated IoT sensors across multiple campus buildings. These sensors provide real-time data on equipment performance, occupancy, humidity, CO2 levels, and more—all while ensuring non-invasive monitoring. This was particularly important given the campus environment. For instance, the sensors can track occupancy, humidity, CO2 and temperature at any space. We made sure the digital twin compliments the school’s existing BMS system and did not replace it. One of the key effectiveness of using new innovative technologies is to add value to existing workflows and build up on it for more efficiency and not necessarily replace it.

In addition, we performed laser scans of all spaces before closing ceilings and walls. This ensures that ten years from now, they’ll still have a record of what’s behind those walls and ceilings. Both the digital twin and inwall scans act as a robust handover package, also IOT data can feed historical data to inform future on campus designs

The benefits go beyond efficient building operation. The smart campus concept provides valuable insights to inform future designs. For example, when planning new buildings, they can use historical data about occupant behavior and system performance from existing facilities. This ensures that future MEP systems are tailored

to actual needs, avoiding overdesign.

Ultimately, it’s about balancing comfort and efficiency—creating spaces that are not only smart and sustainable but also adaptable to the evolving needs of the campus.

Could you share some more details about Windover’s IDEA Platform that you lead.

The IDEA™ platform is a key part of Windover’s innovation initiative, focused on design, engineering, automation and AI. While we are known for our quality brick-and-mortar projects and building great things with great people. The IDEA platform allows us to extend our innovative solutions to the broader AEC community. It’s where we develop innovative tech-first solutions for industry challenges, leveraging our expertise with generative AI, digital twins, reality capture, VR, mixed reality and BIM, to empower construction processes and address challenges even before construction begins.

Since 2020, Windover’s IDEA platform has been supporting projects around North America with BIM Coordination, laser scans and drone surveys. Assisting architects, engineers, owners and municipalities.

One of the unique capabilities Windover has been combing digital prefabrication with BIM workflows. For example, Recently Windover renovated multiple historic buildings façade and interior elements created by hand 120 years ago. Our approach involved laser scans of existing deteriorating façade elements and leveraging additive manufacturing (3d printing) to create exact replicas of the faced. These beautiful elements done by hand 100 years ago, can be replicated with great accuracy, tackling the shortage in skills labor in our industry. This is one way how Windover adopted a mindset of innovation and thinks differently to approach industry challenges. Leveraging technology to empower teams with quality work, upskilling and providing opportunities. Windover unique approach to prefabrication and modular has been evolving or years, thanks to combining leading-edge tech expertise with expert superintendents and projects manages who embrace innovation throughout the project lifecycle.

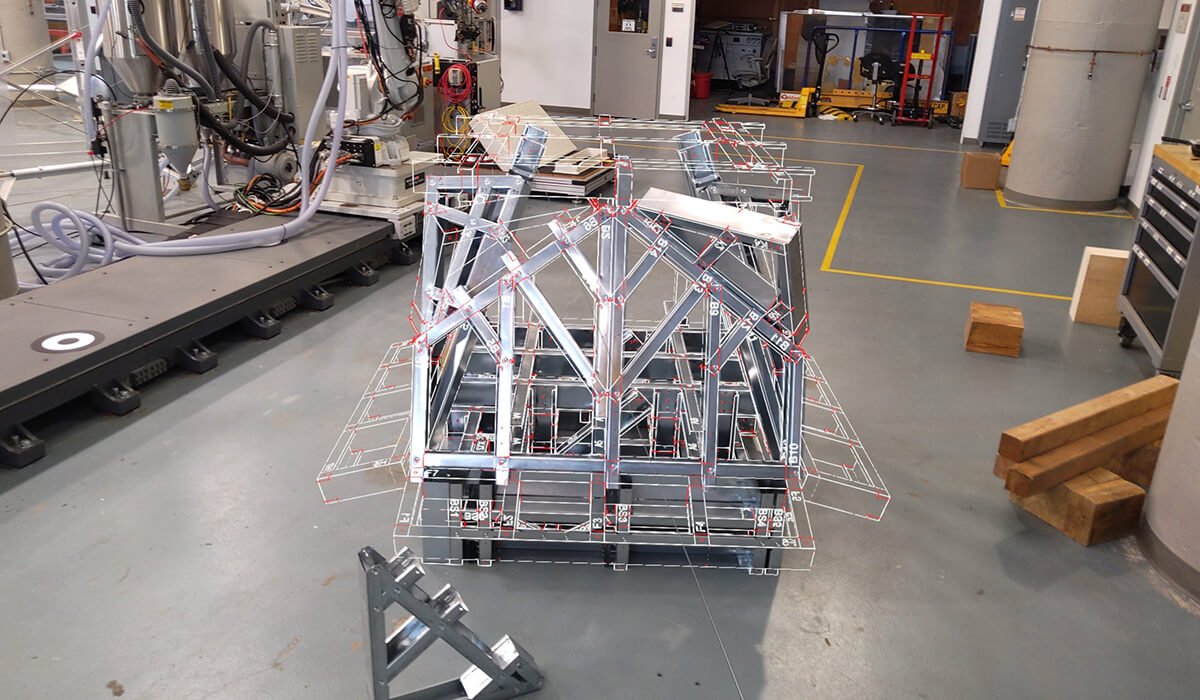

We also completed an exciting AI project in collaboration with Autodesk, The LADG, Howick, Fologram and Stud-io featured as an exhibit at the Harvard Graduate School of Design called In and Out of the Box. This project explored how AI can be utilized to design flexible and adaptive geometries. and integrated mixed reality tools to streamline assembly. The fabrication was done at Autodesk Technology Center in Boston and built by the Windover team. The work was showcased in Howick Steel horizons in Boston and then the exhibition provided Harvard GSD students and community with a firsthand look at the potential of AI in architecture and construction.

The IDEA platform’s mission is to push the boundaries of innovation and improve efficiencies on a global scale. We’ve collaborated with firms in the US, New Zealand, Australia and the UAE, and are now expanding into new markets and partnerships. That’s how we can push innovation in our industry.

Tell me more about your On the Road with Amr podcast.

I’ve been on a global quest for the latest innovations in the architecture, engineering, and construction (AEC) industry. While on this journey, I’ve been having the pleasure of meeting and interviewing industry leaders across Asia-Pacific, Europe, the United States and Asia gathering insights on how they’re thinking outside the construction box to work more efficiently. And I like to share what I’ve learned. In this video and article series, On the Road with Amr: The Path to Innovation, I speak with experts in the field who are increasing construction quality and speed, maintaining the integrity and safety of their workforce, and advocating for sustainable business practices.

At BuiltWorlds AI/ML Conference you will be speaking on a panel about navigating the landscape of ai-powered solutions. Could you share a little bit about your thoughts on that topic now?

Absolutely, Sofie, you’re bringing up an excellent point, especially in the context of this panel. The power of AI is not only in the off-the-shelf solutions—which are fine—but in the most effective way to leverage AI in construction workflows and to tackle specific challenges is combining AI with other technologies such as generative design, BIM or VR. Achieving this requires collaboration across the industry. For example, we collaborated on multiple projects with mixed reality developers, robotics software experts and machinery manufacturers for specific projects, to create integrated solutions. Those solutions would not have been possible to accomplish with only one perspective and a singular expertise area. I will also highlight real-life case studies from Windover projects on the use of BIM and generative AI to streamline efficiencies in the AEC space.

If you are interested in hearing more from Amr you can register for the AI/ML Conference and catch him speaking on the “To Build or Not To Build: Navigating the Landscape of AI-Powered Solutions” panel.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.