Client

Williams Robotics, Inc. is a technology start-up that develops robotic systems created to build homes. The company specializes in designing and manufacturing robotic systems for the construction industry that perform all the quasi-repetitive tasks required for new home construction—framing, sheetrocking, siding, and roofing—and provides customers with a robot that can be deployed to structural building component manufacturers. Williams Robotics, Inc. plans to transform the construction industry by using construction robots to address the lack of reliable labor on-site.

Challenges

Aiming to advance its construction robotic systems to the general market, Williams Robotics faced a challenge because their existing code was complex and hard to maintain and scale up. The company arrived at a decision to clean up and modernize the software, which would bring more reliable robot operations in sorting and nailing profiles and increase robot capabilities.

As far as Williams Robotics is not a large company and did not have enough resources to refactor the code in-house, the company searched for a vendor with unmatched experience in the construction industry and robotics sphere. Known for extensive expertise in robotics simulation and programming, AMC Bridge was selected for the project.

Solution

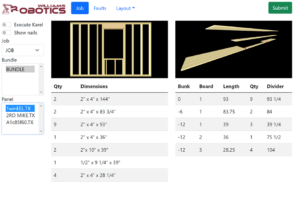

AMC Bridge was entrusted to refactor the existing code used by FANUC® robots for sorting and nailing wooden structures. The purpose was to make it scalable and easy to maintain. However, the project quickly gained a more ambitious goal due to AMC Bridge engineers’ deep expertise and initiative augmented by the client’s willingness to master the product. Thus, on top of code improvement, the robot’s building speed and precision were enhanced while the range of supported wooden profiles was extended.

As a result, the AMC Bridge team provided scalable and easy-to-maintain code with the program stability verification resulting in the following sorting and nailing enhancements:

- Improved recognition of existing wooden profiles.

- Error handling.

- Additional converters for different input file types.

- A range of recognized profiles extended with new types.

- A new algorithm for configuring profiles sequence.

- User-friendly nailing parameters setting.

- A new nailing algorithm that rests upon geometry and allows quality nailing and smart nail placement.

- Validation of driven nails.

- A new user-friendly log for output data verification.

- Automated testing of large quantities of wall panel definition files.

- Automated regression testing.

- A modified Human-Machine Interface (HMI) that enables easy navigation and usage.

- A new tool for generating automated reports on software stability.

Process

Having received the client’s business requirements, the AMC Bridge team went ahead with the work on code improvement.

The project included the following stages:

- Refactoring the existing software.

- Developing and implementing additional functions.

In the first stage, the main problem for the team was the absence of documentation on the integrated development environment and on the software language Karel, as it is a seldom-used programming language. So, the AMC Bridge team had to complete extensive research on those issues and study the language. Hereupon, AMC Bridge analyzed the code, optimized it, and performed bug-fixing. In line with that, AMC Bridge team members prepared a document on possible further improvements.

In the second stage, the AMC Bridge team discussed the plan of improvements with Williams Robotics, received guidance regarding the priority of tasks, and implemented the agreed new features and modifications, including error handling, automated reporting, converters for different input file types, enhanced HMI for reviewing wall profiles, and so on.

Code stability was ensured by the continuous delivery of builds. To maintain collaboration during the development process and receive valuable feedback, a live session was held where the client showcased the code behavior on real robots.

Results

AMC Bridge improved existing code for operating FANUC robot’s sorting and nailing actions and added new features, which significantly increased robot productivity, reduced the number of errors, and accelerated the sorting and nailing processes. The automated software stability verification decreased the number of actual robot test activation. Native navigation with user-friendly HMI made it possible to verify and manage sorting and nailing processes from day one without requiring extra training.

On top of that, the extended range of supported wooden profiles made by various manufacturers scaled up the list of customers willing to build homes with Williams Robotics and resulted in increased build precision, creating a distinct competitive advantage for Williams Robotics and enabling them to offset the labor void on-site.