We have written at length recently about the changes afoot in the realm of equipment management, but equally interesting are the ways contractors such as W.M. Jordan are modifying their equipment with reality capture cameras and other technology to make it into “smart equipment.” Frustration with the perception of the construction equipment manufacturer’s pace of bringing integrated smart technology to their products by comparison with what those contractors experience in their own passenger vehicles, combined with inspiration by what is happening in other industries, has spawned a slew of smart equipment start ups, giving engineering and contractor VDC and technologist groups a reason to get their hands on the actual equipment we use to build our projects. They are liking what they are finding and the industry’s whole approach to construction equipment may never be the same.

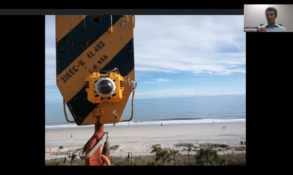

In one case study, we met with Chris Machut, Chief Technology Officer, Netarus HoistCam, Raynald Morris, CTO & VDC Director, WM Jordan, and Geoff Bean, Virtual Construction Coordinator, WM Jordan to learn about W.M. Jordan’s experience with using Netarus’ crane-mounted reality capture technology on one of their projects.

Wireless camera system that can be easily and rapidly deployed on tower cranes and telescopic boom cranes is just one illustration of the ways in which contractor VDC groups are increasingly “modding” their equipment to make it smarter. W.M. Jordan is a construction management and development company headquartered in Newport News, Virginia. A mid sized firm, working in diverse markets, they are about a $500 million a year contractor. Jumping to about minute 9:00 of the talk, we hear about the types of challenges contractors face with their cranes and particularly with visibility and how those challenges provide the initial rational for adding the cameras to cranes. It is an obvious play for anyone who has experienced the sensor and camera capabilities of any recent model passenger vehicle.

Beyond initial use cases, around minute 13:00 of the talk, we hear about how the virtual design and construction group began further exploring the cameras and the possibility of added value in the data collection, considerations around implementation, and where those possibilities might lead.

The W.M. Jordan and Netarus case study is just one illustration of the way that engineering and contractor technologists are no longer waiting for the equipment suppliers or others to bring them solutions incorporating the kinds of advances they are seeing made available in consumer or other contexts. Instead, engineers and contractors are increasingly finding start ups and working with them to modify their existing equipment to produce better results, and, as this case study illustrate, the more the VDC and other technologists get comfortable with the equipment, the types of data they can generate, and how the data be integrated with other systems, the more benefits they are beginning identify and the more facile they are becoming with the application of the technology in the field.

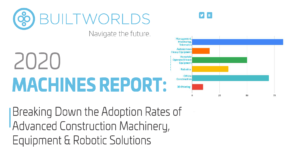

If you are interested in other case studies around advances in equipment and equipment management, you may wish to access our Machines Report (click the image below) or our regular Machines Analyst Calls and Recordings. Our November Machines Call will look at how Autodesk and Milwaukee Tool have created an integration to help facilitate learning for project management from equipment-generated dated. To find out more about that session, click on the event below, and to learn more about how to gain access to a whole year of all of our research, programming, and other resources, simply visit our member network page for options.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.