Leading up to our Machines Conference, we wanted to present you with some of the leading emerging players in built world machinery innovation. As we pulled together the most trailblazing players, one theme was clear: the future of construction machinery is increasingly automated. It’s one of the fastest developing sectors in construction industry technologies, as the construction industry scrambles to meet growing demand with a shrinking skilled workforce. The leading solution theory? Enhanced automation leads to greater productivity and allows skilled workers to attend to more specialized tasks.

For several years we’ve seen the industry giants focus their R&D on automated equipment: Komatsu has already deployed the world’s largest fleet of autonomous heavy mining machinery and has recently announced that they’re fast-tracking AI in construction machinery through a partnership with Nvidia. Cat Connect and Trimble Machine Control have been consistent leaders in heavy machinery guidance and task optimization.

Interested in the future of automation and robotics in construction? 25 experts are discussing the topic in-depth at our Machines Conference on May 3rd in Chicago.

These companies have proven the technology and in doing so, paved the way for startups to further explore the limits of our machines.

From automated milling to rebar-tying robots to onsite 3D printer buildings, these 15 innovators are giving our equipment new life. Some of these technologies have been deployed for years and others exist only as prototypes, but all are uniquely redefining machinery and the way we use it.

Want to read this report offline and get additional insights?

Download the PDF version of this report at the end of this article.

Automated Bricklayers

Construction Robotics – SAM100

You’ve surely seen this robot before, and you probably have opinions about its aptitude as a bricklayer. Still, the fact remains that since its debut in 2015, SAM100 maintains its lead as the only automated bricklaying solution on the market (with a price tag of about $400,000). As Construction Robotics continues to make improvements to its functionality, you should expect to continue seeing this dude all over YouTube.

Fastbrick Robotics – Hadrian X

Though still in its prototyping stage, the automated mason Hadrian X from Fastbrick Robotics differs from SAM100 in key ways. Most noticeably, it isn’t locked down to a track, but rather can be positioned onsite where its long crane-like arm can lay bricks at any angle and in whatever configuration the design calls for. Which leads to its next standout characteristic: after CAD files are uploaded directly to the robot, it autonomously follows the design, end-to-end.

3D Printing Machines

Genesis Dimensions

Genesis Dimensions is developing an onsite 3D printer that uses their proprietary building material Duraganic to print structures that “will look like an ICF building, but the construction process will be fully automated,” says CEO Kaleb Steinhauer. Their “print crawler,” which will soon have a reach of 100 ft, operates autonomously and prints customized designs.

ICON – Vulcan 3D Printer

![]()

ICON’s proprietary Vulcan printer is designed for home construction but differs from Genesis Dimensions’ printer in that the concrete extruder runs on a large track suspended over the print site. The system is currently capable of printing an 800-sq-ft house, which they’ve proven this past March (with their partner organization, New Story) in Austin, TX. What’s more, the house is now the country’s only fully-permitted 3D-printed home. While other similar companies struggle to find the best printable material for the job (cost, strength, etc), ICON claims to have built their liveable home for under $10,000.

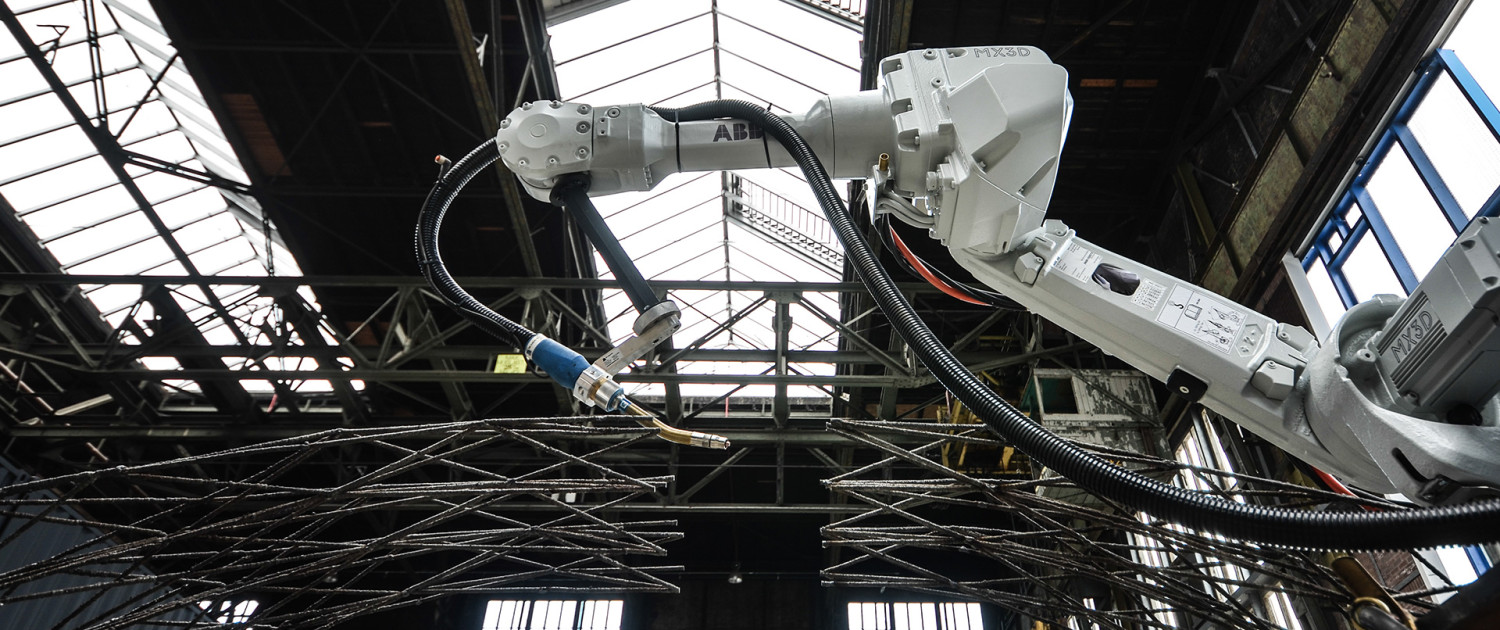

MX3D

This 3-year-old startup is 3D printing a steel walking bridge that, when completed inside their Amsterdam workspace, will be installed on the Oudezijds Achterburgwal canal. Making this possible is MX3D‘s proprietary 6-axis robotic printers, programmed with their own developed automation software. Though a huge achievement in its own right, you can look at this bridge as a groundbreaking proof of concept for complex 3D printed steel construction.

Automated Tools and Equipment

Blueprint Robotics

Rather than providing modular structures, Blueprint Robotics takes their customers’ designs and fabricates walls, flooring, and roofing according to customer specifications (down to the millimeter) using a team of highly-optimized robotic carpentry tools. This automated production line allows the company to deliver projects ahead of schedule, meeting quotes, while maintaining full customization.

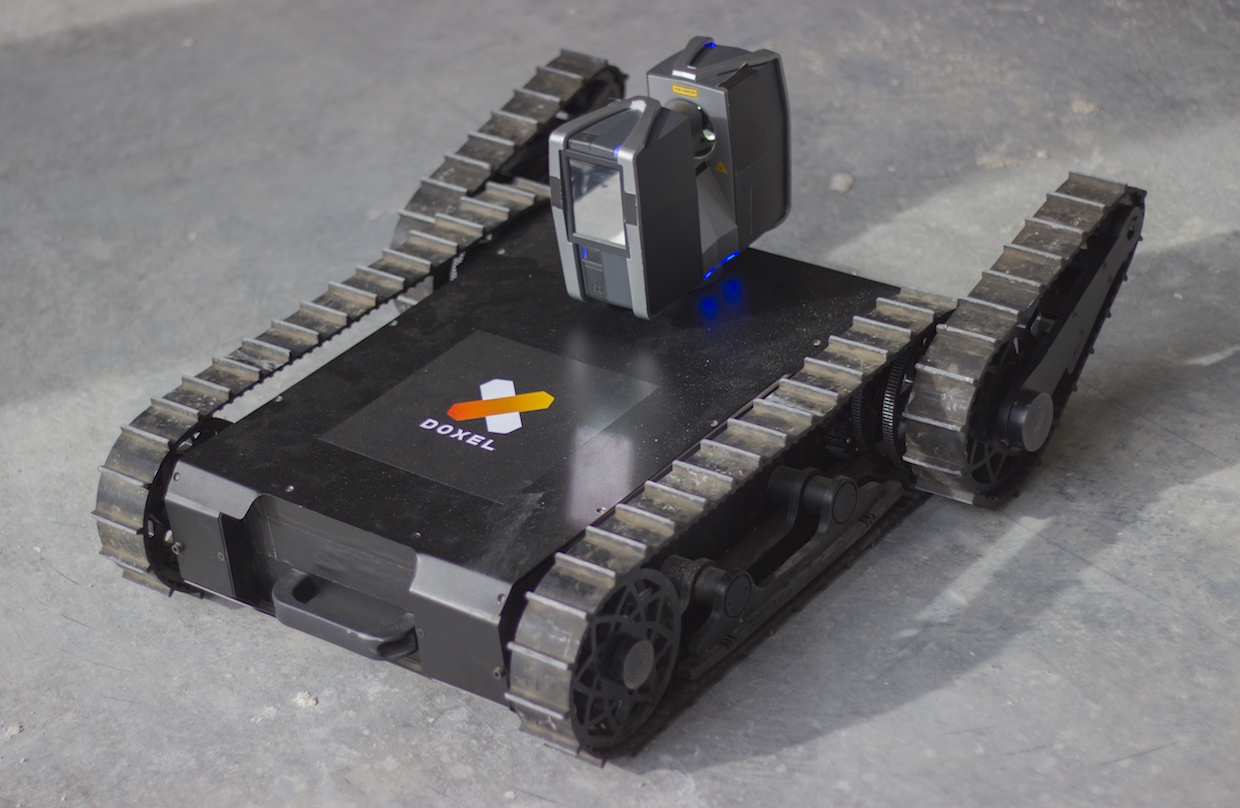

Doxel AI

Doxel has developed a fully autonomous rover bot that can roam large-scale jobsites and assess progress. Using 3D scanning and deep learning abilities, the robot will compare installations to the project schedule, determining which tasks are running behind, and sending reports in real time. This little robot is ready for work and looking for projects with contract values exceeding $20 million.

HAL Robotics – CAMERA Project

Recently unveiled in London, the Construction And Manufacturing Enabled by a mobile Robotic Arm (aptly abbreviated as CAMERA) is a versatile robot for jobsite assistance. Its goal is primarily to be a collaborative worker, autonomously following a CAD model to assist the human workers by pre-drilling, measuring and marking, and reaching tricky areas using its scissor lift platform and agile robotic arm. The collaborative design team of HAL Robotics, ABB, Skanska, and InnoTech UK hope to universalize their software to power a range of robotic helpers in the near future.

Skyline Robotics

These window-cleaning robots aren’t afraid of heights. Even the tallest, curviest, most window-clad skyscrapers can be tackled by this fearless team. They use their machine-learning skills to acquaint themselves with the design of the building and optimize the most efficient route for cleaning every inch of glass on the facade. Skyline Robotics isn’t stopping with window cleaning, though, as they have plans to provide robotic replacements for further dangerous urban tasks in the near future.

Spatial Timber Assemblies

Regardless of the design’s complexity, the robotic arms created by Spatial Timber Assemblies are equipped with the tools and programming to do the job. They automatically change tools, cut timber to length with CNC-type hardware, pre-drill holes for assembly, and position the beam so a human worker can bolt it into place. The high level of accuracy allows architects to design significantly more complex structures with wooden load-bearing frames.

True Autonomy

Michael Lawrence of True Autonomy is developing a versatile autonomous navigation system that attaches to construction machinery to perform repetitive tasks on their own. The system has been proven with concrete floor polishing, though the technology will eventually be applicable to small machinery used all around construction sites.

TyBot

TyBot’s fleet of rebar-tying robots navigate bridge decks autonomously, using sensors to identify intersections without the need for project-specific designs or programming. It’s a repetitive and backbreaking task that TyBot can accomplish at any hour of the day without injury or intervention.

Heavy Machinery

5D Robotics

Position tracking and navigation have moved well beyond GPS. 5D Robotics has developed their 5D node technology which employs an array of sensors from LiDAR to Ultra Wideband to work in tandem to control the position of the guided machine to within a 2-cm accuracy. The plug-and-play nodes can autonomously navigate shuttles, material handling vehicles, forklifts, and surveying drones (to name a few) and have proven their effectiveness in projects worldwide.

Built Robotics

The 2-year-old startup has made many headlines as it quickly moves toward deployment of its fully-automated track loader. Pairing GPS and LiDAR to allow their machines to navigate themselves, Built Robotics has proven through test jobs that their loaders can complete tasks quickly and with high levels of accuracy.

Cooper Gray Robotics – ROEBL

The Remote Operated Electric Bucket Loader (ROEBL) will work in conditions too hazardous for human operators (falling debris, toxic vapors, steep grade), and will do it without emitting diesel fumes around the site. Cooper Gray Robotics‘ trademarked Smart Control technology allows the machine to be steered by remote control (eventually autonomously) at a safe distance and with precision. The company is seeking further investments before taking their ROEBL to market, but keep an eye out for when they do.

DOWNLOAD THE FULL REPORT HERE:

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.