by TODD STOLARSKI and ROB McMANAMY | Jul 21, 2015

Thanks to Shakespeare, the Danes are oft-associated with melancholia. But today, that dark script is being rewritten by the lighthearted and constructive souls at MX3D, the Danish startup known for multi-axis robotic metal 3D printing systems. Its latest project may well upend the international construction market as we know it.

This summer, MX3D has teamed with Amsterdam, a city with its own 3D Printed Canal House, global software giant Autodesk, and Heijmans, the Dutch contractor behind smart highways and those glowing Van Gogh-inspired bicycle paths. The group goal? To create a 3D-printed metal footbridge that will lead to a full-scale, steel span in 2017.

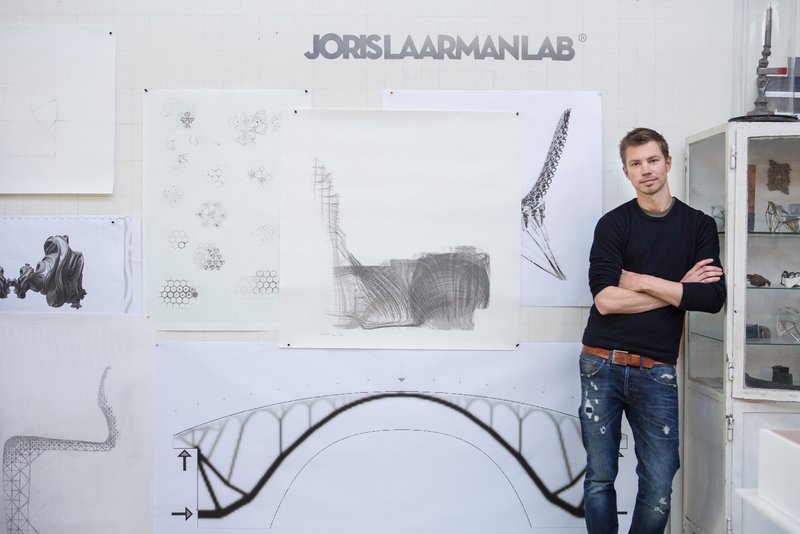

“This bridge will show how 3D printing finally enters the world of large-scale, functional objects and sustainable materials while allowing unprecedented freedom of form,” says Joris Laarman, designer and founder of Joris Laarman Lab, a self-described “experimental playground” that works with craftsmen, scientists, engineers, and new technology. “The symbolism of the bridge is a beautiful metaphor to connect the technology of the future with the old city, in a way that brings out the best of both worlds,” he adds.

For its part, MX3D calls the project “a bridge to the future in the ancient capital of innovation.”

Contractor Heijmans’ goal is to create an automatic construction site. Last month, Jurre Vand der Ven, innovation manager at Heijmans Infra, its infrastructure unit, told 3D Printing Industry: “Heijmans realizes things must change. We are perfectly compatible with MX3D because we share the same outlook and will be able to build it together…We will be testing for the first two years, but want to effectively start printing the bridge in year three.”

Added Heijmans Infra business development manager Jan van de Ven, “Robots, which were previously only suitable for serial production, are now able to do a great deal more, thanks to today’s ‘computing power’ and the user-friendliness of software. On-demand is quickly increasing in popularity in all sectors. In addition, there is increasing demand for special shapes – and everything has to be as cheap as possible. 3D printing is the culmination of all these requirements.”

Developed in 2014, the MX3D-resin printer already has evolved into a new robot which, together with an advanced welding machine, is able to print with metals, such as steel, stainless steel, aluminum, bronze or copper, without the need for support-structures. By adding small amounts of molten metal at a time, the machine is able to “draw” metal lines in mid-air.

In September, a visitor center will open in Amsterdam, where the public can follow the project’s progress. Joining Autodesk and Heijmans in supporting the effort are Air Liquide, ABB Robotics, STV, Delcam, Within, Lenovo, and public partners TU Delft and the Amsterdam City Council.

Below, Joris Laarman, and the magic pen at MX3D…

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.