The Value of Managing Your Materials

Materials management solutions are becoming increasingly important in the construction industry as contractors look for ways to improve efficiency, reduce waste, and increase profitability. With recent supply chain issues under the global spotlight, these solutions are increasingly critical to managing what is a massive risk, and opportunity, to any construction project. The intended results of the increased use of technology to manage materials are reduced costs, increased productivity, and a better overall project outcome.

As an extreme example of the importance of materials management, Walmart recently reported it loses nearly $3B annually due to stolen or lost goods. This is of course not a direct comparison to the construction industry; however, it highlights the massive importance of taking care of the materials required for successful construction. Considering labor costs only account for somewhere around half of the total cost of a typical commercial construction project, material costs therefore account for a significant portion of our built environment. Given the inherent complexities of the supply chain, the jobsite, and installation, it is clear that adequately receiving, tracking, and installing materials is a key risk to any project.

Research in Materials Management

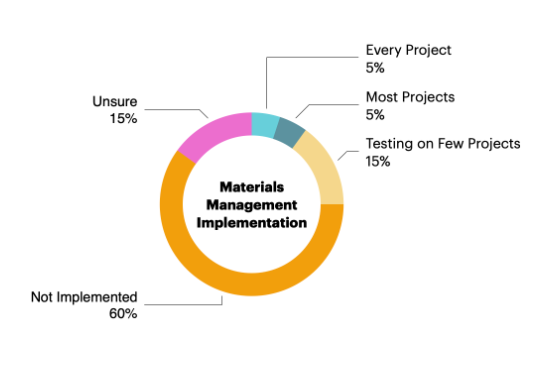

According to 2022 BuiltWorlds Benchmarking Research, there is a relatively large disconnect between the perceived risks associated with materials management, and the technology solutions available to the contractor crowd. In fact, materials management technology solutions are one of the lowest areas of adoption of any technology specialty area. What the figure above shows is contractors, and specifically larger contractors, are starting to get interested in these solutions, but there is very minimal adoption on an enterprise level.

A key benefit of materials management solutions is improved inventory tracking. The use of technology in inventory tracking allows contractors to have real-time information about their materials, including the quantity available, location, and delivery schedules. This makes it significantly easier to manage materials on site and reduce the risk of materials being lost or stolen. Additionally, inventory tracking helps contractors to avoid overstocking or understocking materials, which can result in unnecessary costs or project delays.

What is Available - 4 Leading Solutions

Despite the low adoption metrics, there are visionaries in the industry advancing and seeking to advance the solutions available for materials management activities. Below are some solutions BuiltWorlds research has identified as having the capabilities to improve materials management functionality:

- SiteSense - An Intelliwave product that provides construction projects with full visibility and control of project materials from the supplier’s facilities to warehousing to site delivery to storage to staging and on to installation.

- Jovix - A Hexagon company that provides an interface for material coordinators, work planners, and construction management teams to effectively plan activities and support the schedule.

- Voyage Control - A logistics platform that coordinates and tracks all site logistics including locations, deliveries, and material placement

- Viewpoint - A trimble company including a module which allows contractors to forecast, identify, and communicate materials management needs

WANT TO LEARN MORE?

Interested in learning more about BuiltWorlds Benchmarking Research? Click here to understand how we gather data, and participate in our upcoming research programs!

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.