The construction industry offers numerous opportunities for the implementation of robotics. Today, contractors have implemented robotics onsite for tasks such as bricklaying, site inspections, demolition, material handling, layout, and drywall installation. Robotics in construction can improve efficiency, safety, and precision for contractors by automating repetitive tasks, reducing human error, and minimizing hazardous conditions onsite.

Despite the strong case for construction robotics, many general contractors have faced challenges in fully embracing robotics on a large scale. According to BuiltWorlds' latest data on robotics adoption, over two-thirds of those using construction robotics to any degree are still in pilot programs or testing phases. The interest is there, but widespread adoption remains a distant goal for most GCs.

The ROI Hold Up

The primary challenge is the return on investment - ROI is typically calculated by the scope of a single project, while the long-term benefits of robotics remain largely overlooked and untapped by GCs. Despite the promising applications, this adoption hurdle makes the case for construction robotics a harder sell, especially for small to midsize contractors who tend to be more risk-averse than their larger peers.

Adoption Soars In Industrial and Service sectors

The adoption of robotics in industrial settings such as manufacturing, logistics, and warehousing has surged in recent years, with automation expected to make up a significant portion of industrial companies' expenditures over the next five years. Robotics have been used in manufacturing since the mid-20th century, aiming to enhance efficiency and reduce labor costs. With advancements, robots are now capable of performing complex tasks, transforming production processes, and increasing precision and productivity.

The adoption of robotics is particularly high in the logistics and fulfillment industries, where robots efficiently handle tasks such as materials handling, palletization, and sorting. Furthermore, the service industry has seen an increase in robotic innovations, particularly in hospitality, food service, delivery, and customer service, driven by factors such as the COVID-19 pandemic and labor shortages.

The Construction Industry Remains Unstructured & Unprepared

While we can commend the use of robotics in manufacturing, warehousing, and service industries, we must also recognize that the construction industry presents unique challenges and additional variables compared to other sectors. These variables include the unique nature of each project, diverse site conditions, a wide range of stakeholders, less standardization in processes and materials, and the reliance on skilled labor, which can vary greatly in availability and expertise. Additionally, construction projects often face unpredictable factors such as weather and regulatory changes, adding further complexity and variability compared to more controlled environments, like manufacturing.

What Construction Robots Do Well

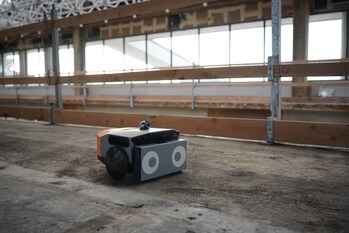

BuiltWorlds’ research in Tools, Equipment, and Robotics sees most construction robotic solutions falling into one of the following categories: autonomous vehicles/heavy equipment, demolition robotics, monitoring robotics, and service/labor robotics. Most companies in the construction robotics industry design specialized solutions or a set of solutions to fulfill a specific function during on-site construction projects. Many of these solutions are primarily used during a particular phase of the project lifecycle. Construction robotics excel in the structured aspects of a construction project lifecycle, where tasks are repetitive, the environment is controlled, and the work can be executed without interruption.

In many industries, especially those with widespread robotics adoption, there can be cultural hesitations regarding robots replacing human jobs. Yet in the construction industry, leveraging robotics is a safety measure. It enables workers to step back safely from hazardous job sites and lets specialized equipment play a leading role.

What's Left To learn

With a more intentional focus on robotics and the removal of some hurdles to adoption, the construction industry could achieve great results. While the comparison to industries with more established robotics usage may seem inequitable, it can catalyze innovative approaches to widespread adoption. Here are some examples of strategies that leading industries have used to advance adoption of robotics:

- Adaptability & Flexibility: Multipurpose robots can deliver significant cost savings—and have proven their effectiveness in several industries. For example, OTSAW’s Camello+ is an autonomous multi-purpose robot that serves diverse needs in delivery and security applications.

- Collaboration & Partnerships: A path to success in construction robotics could be with solution providers partnering on combined robotic solutions. An example of this is the partnership with Robotiq, a manufacturing and warehousing robotics company, and Universal Robots, a collaborative robotics company. By focusing on UR robots, the partnership has allowed Robotiq to develop off-the-shelf integrated solutions for robotic applications for its robotic arms and grippers.

- Workforce Engagement & Upskilling: Engaging your workforce on how to work with and alongside robotics is a crucial step to keeping them engaged, involved, and excited about new innovations on-site. Mobile Industrial Robotics, a warehousing and logistics robotics solution provider, provides online training modules and global in-person training for the maintenance, operations, and commissioning of their robots.

Up next...

The conversation around robotics will take the stage at BuiltWorlds’ upcoming Construction Tech Conference. Join us for "Automating Construction and Maximizing Efficiency with Robotic Solutions" and a full slate of other panels.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.