With BuiltWorlds’ AI/ML Research Track under way, it’s clear that construction industry innovators continuously seek new avenues to gain an advantage through the use of artificial intelligence and machine learning in their businesses.

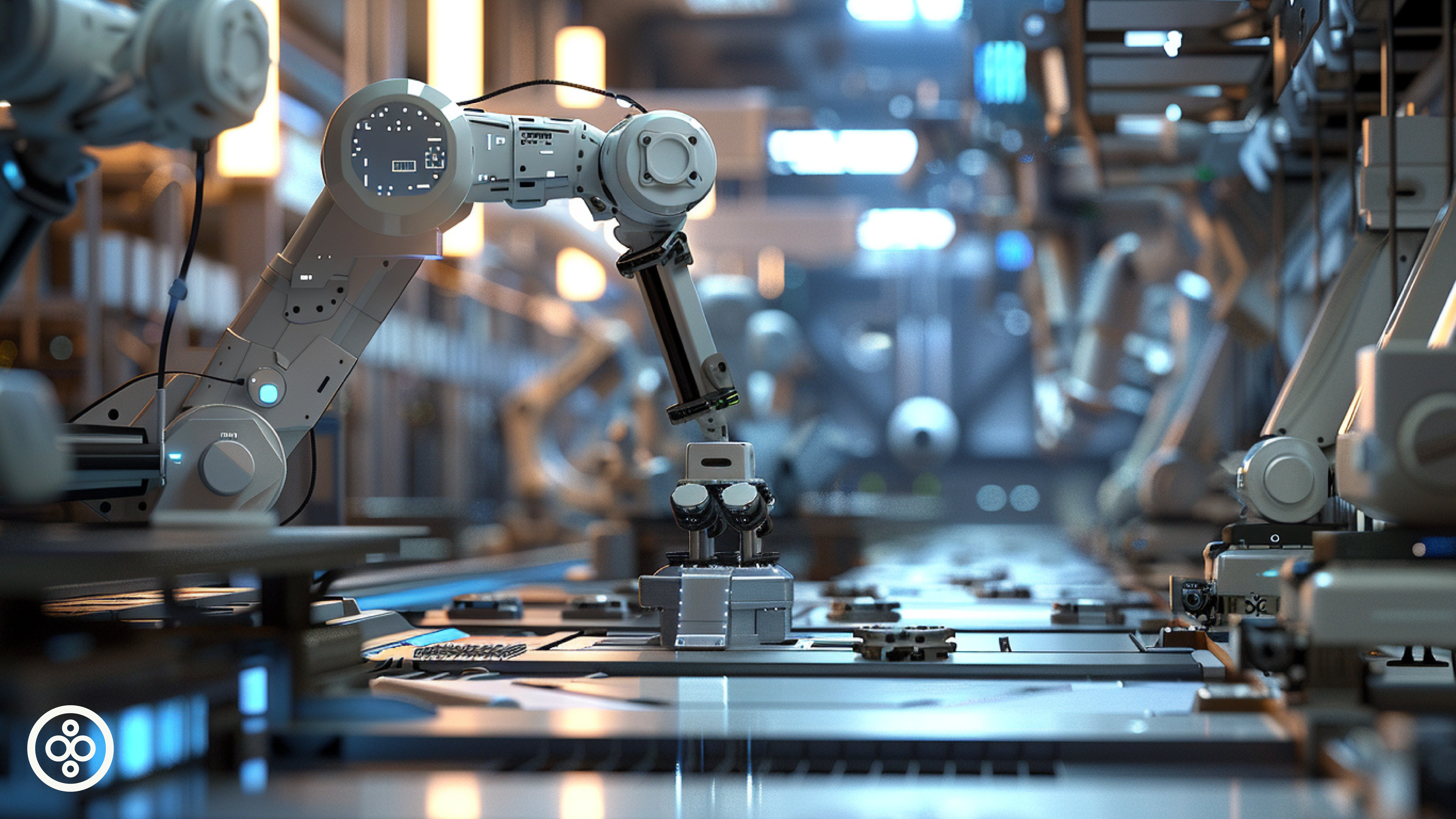

Sharing case studies and discussions of trials and pilot programs are invaluable to the advancement of the industry, but there is still much to learn through similarities and differences of activities with other industries. The manufacturing industry, for example, has witnessed significant AI integration and automation techniques worth studying.

Three key similarities between the two industries are 1) a journey to operational optimization, 2) safety monitoring and enhancements, and 3) data-driven decision making efforts. Though various factors, particularly industry fragmentation and environmental complexities, prevent the industries from growing in concert, businesses in both industries seek improvements in each of these three key areas.

The following case studies and considerations may help us better understand the potential impacts of AI/ML on the construction industry.

1. Operational Optimization

One example of the use of AI for operational optimization in manufacturing is Bosch’s integration of AI analytics into over 1,400 of its production lines worldwide. Combining the use of air sensors, cameras, and other data-collection hardware, Bosch collects billions of data points that machine learning algorithms have been trained to collect, process, and report to ensure the most efficient and highest quality production. One specific use case of AI is in production scheduling, where data is inputted into an algorithm to optimize part procurement and sequencing.

There are various parallels to the construction industry, including the implementation of AI to optimize procurement, scheduling, and quality control processes.

2. Safety Monitoring & Enhancements

DOW Chemical implemented a computer vision system trained to detect potential environmental hazards as well as worker practices. Continuously run cameras have the ability to detect equipment failures and factory risks, while additionally trained to detect unsafe worker behavior. Additionally, the implementation of drones and robotics to perform difficult or unsafe tasks provides the ability to eliminate unsafe conditions.

Parallels to the construction industry include site capture solutions with the ability to detect unsafe site conditions and/or unsafe worker behavior. Additionally, the rise of jobsite robotics or effective wearables solutions may allow contractors to remove repetitive, high-stress, or unsafe activities.

3. Data-Driven Decision Making

Supply chain management and materials procurement are critical to the success of any project. Amazon’s business model relies heavily on its ability to maximize the efficiency of its inventory and supply chain systems. AI allows Amazon to forecast and optimize its ability to produce orders and manage shipments to provide the materials required for its sales orders.

The fragmented construction industry is notorious for its lack of visibility into procurement activities. From paper and excel procurement logs to phone calls with shipping companies, tracking material orders continues to be a difficult task. The ability for AI to track materials from submittals through delivery is a critical opportunity for technology.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.