San Francisco-based start up StructionSite allows project team members to view construction site conditions from an entirely different angle. By capturing spherical imagery generated by a consumer 360 cameras, a StructionSite app allows stakeholders to walk the job site from their mobile devices, browsers – even a virtual reality head set – for purposes of evaluating quality, progress and clashes. Among the advantages are “context and speed,” said StructionSite CEO Matthew Daly, who co-founded the enterprise with Philip Lorenzo in November 2016. “Viewers can identify a particular system or component within a more encompassing environment,” Daly said. Project team members additionally appreciate the system’s rapid photo capture, he added.

The app also accommodates standard directional photos and promotes ease of access and retrieval. StructionSite has come a long way in a short time. Among other initiatives, it joined project management software giant Procore Technologies‘ App Marketplace in October. Here, Daly details the new technology.

With the proliferation of mobile devices, photo documentation of project sites is booming. What did you have in mind when you founded StructionSite?

MD: We didn’t begin with photo documentation in mind. The idea was to digitize the job site to provide visual context and augment the existing process of managing projects with models and drawings. We appreciate the concept of creating models and attaching photos of site conditions to drawings. However, we asked ourselves, “What could we achieve by creating a visually accurate version of the job site, such as those generated by laser scanning?” At issue was the time and expense of digitalizing a job with a laser scanner several times a week, without the ability of linking resulting information to bidding, estimating and project management apps.

How does StructionSite generate its imagery?

MD: We’re able to do so thanks to proliferation of consumer 360-degree cameras. The camera is omnidirectional, embedded with several camera lenses that simultaneously capture overlapping angles, then stitches the various images to create a single spherical video piece. Users upload the imagery with our app and attach or locate it in a corresponding floor plan hosted in our cloud, where it can be accessed by other project team members.

What party generates the floor plans?

MD: We use the same plans as those used by the contractor, which simplifies the process. We’re able to integrate with Procore, Egnyte and Box to pull the plans and store them on two systems – ours and the contractor’s, with the latter’s used for final turnover to the owner. Our thinking was that linking the imagery to a corresponding space on the floor plan would facilitate quick retrieval when issues arise.

What other features simplify storage and retrieval?

MD: All photos are tagged with date and location on a drawing, making them easy to sort and filter at anytime during the life of the building. When you want to know if you can break into a wall or slab, this information can save the owner thousands of dollars for each occurrence.

- Easy Access: Linking the imagery to a corresponding space on the floor plan facilitates quick retrieval of imagery when issues arise.

In what ways does the system save time in executing work in the field?

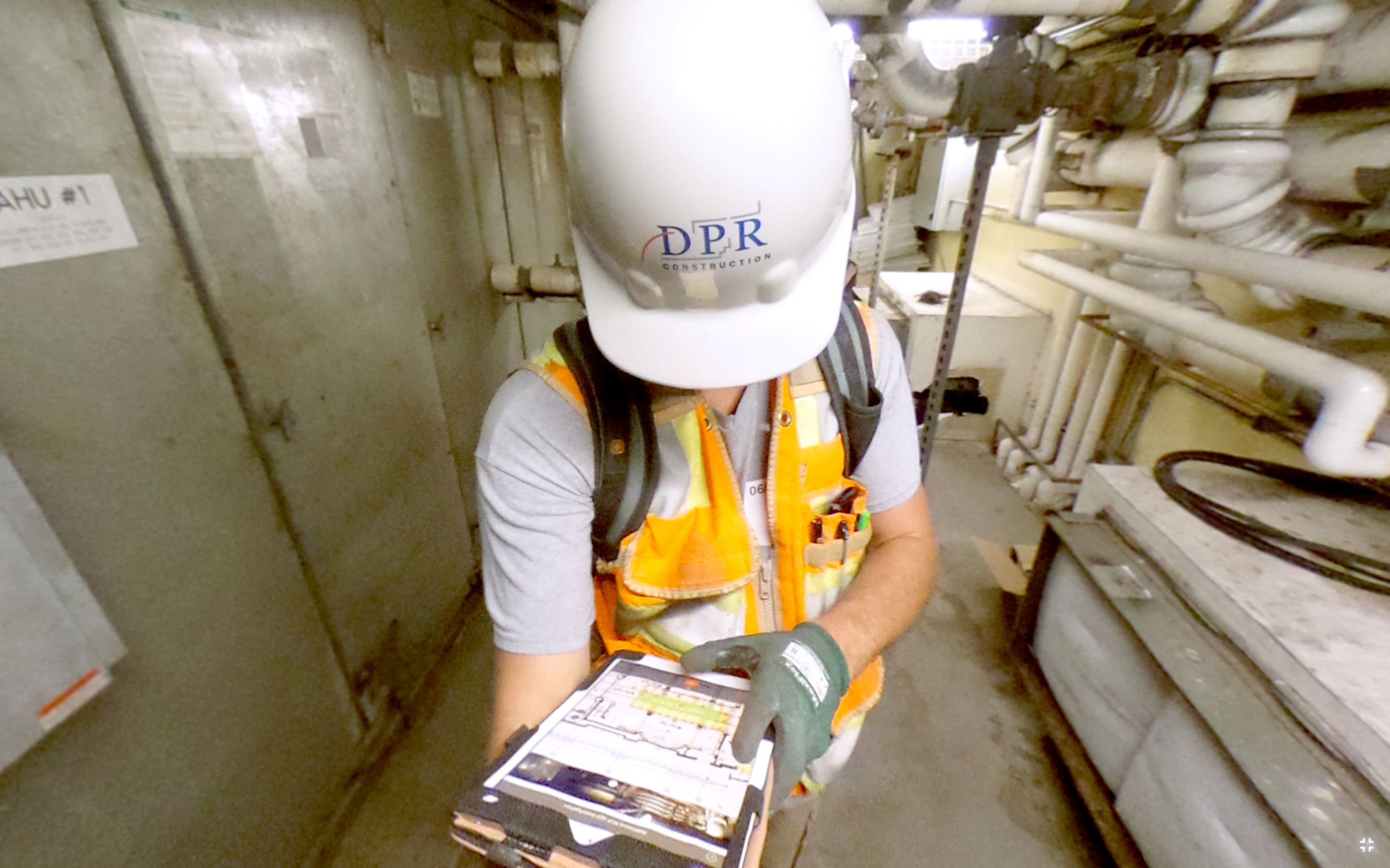

MD: Here’s an example. A superintendent with DPR Construction recently told me he saves three to eight hours a week updating his P6 project schedule by photographing a space, calling it up in his office, and comparing it with a schedule he simultaneously is referencing. Updating the schedule this way leaves no room for doubt about the status of construction or percent completion at any given time.

“Viewers can identify a particular system or component within a more encompassing environment.”

Matthew Daly, CEO and co-founder, StructionSite

Assuming a problem such is detected, how who does the system address it?

MD: The party that identifies the problem opens up a conversation thread by notifying other stakeholders who can be accessed by browser, mobile device – even email. Users familiar with enterprise chat applications such as Slack and Yammer will notice speed in communication and user experience. The key difference here is that the conversation is happening within the context of the real job site via a 360-degree photo – kind of like Google Street View + Slack for construction teams.

How does the program support maintenance and management of the facility once handover occurs?

MD: An X-Ray function allows the user to “see through walls and slabs,” meaning the facility can perform a live overlay of historical construction photos within the real world, allowing that user to view or verify the equipment located behind it. If the space undergoes reconfiguration or repairs, you could easily upgrade the old documentation with a replacement photo by adding the new photo to the existing pin.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.