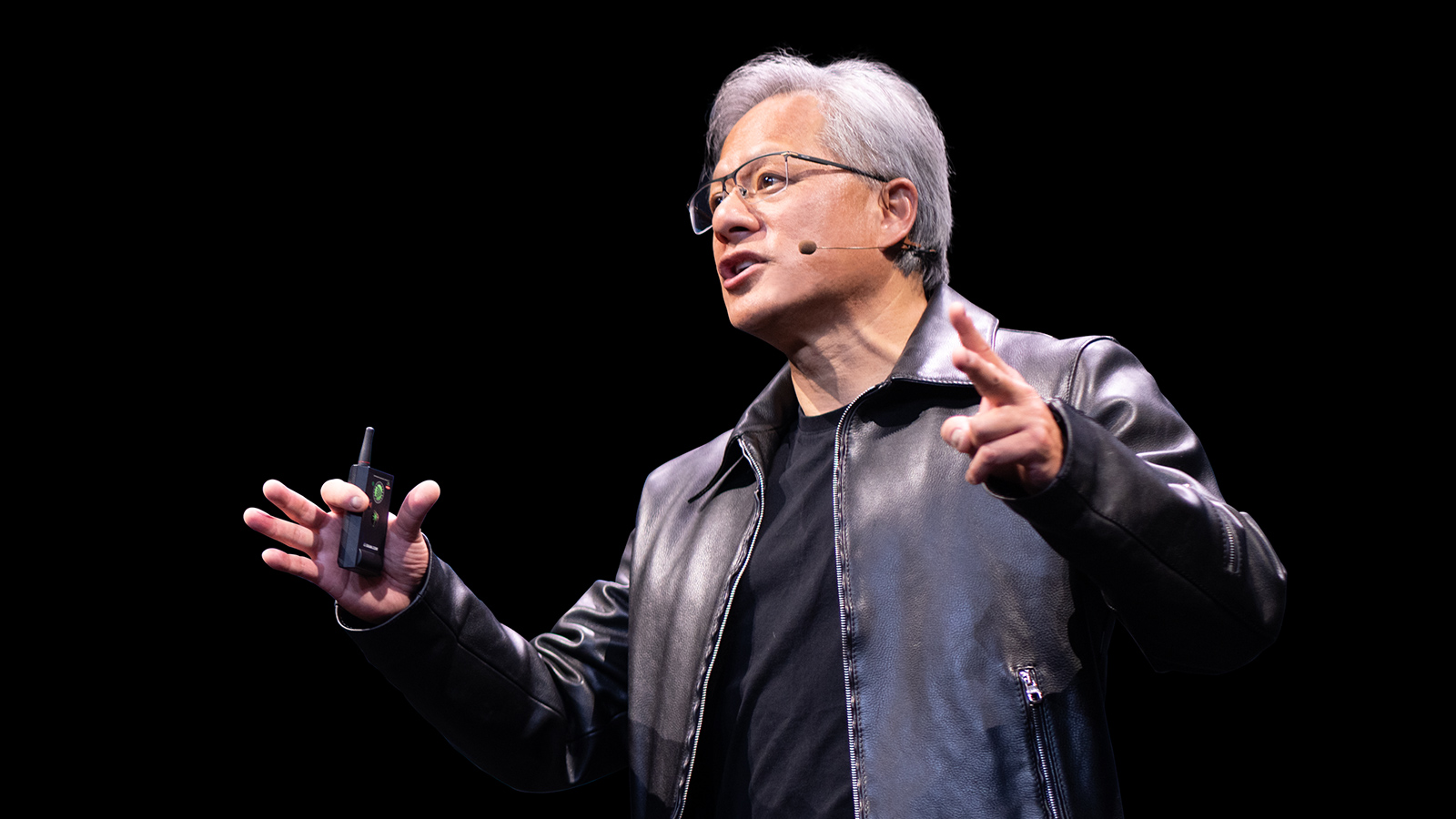

While artificial intelligence and machine learning technology are still new concepts, the majority of us now have at least a loose understanding of what that technology entails. However, how many people have heard of physical AI? I know I hadn’t before stumbling upon this Forbes article with Nvidia CEO Jensen Huang on the subject.

Huang proposes three different phases of AI. First, there was "Pioneering AI," a foundational phase for the models and tools that have gone on to power the next stage.

Currently, we are in what he calls the "Enterprise AI" phase. This period is characterized by the growing prevalence of AI models and chatbots, increasing enterprise-level efficiency. Enterprise AI applications can look like chatbots, predictive analytics, and AI-driven design tools.

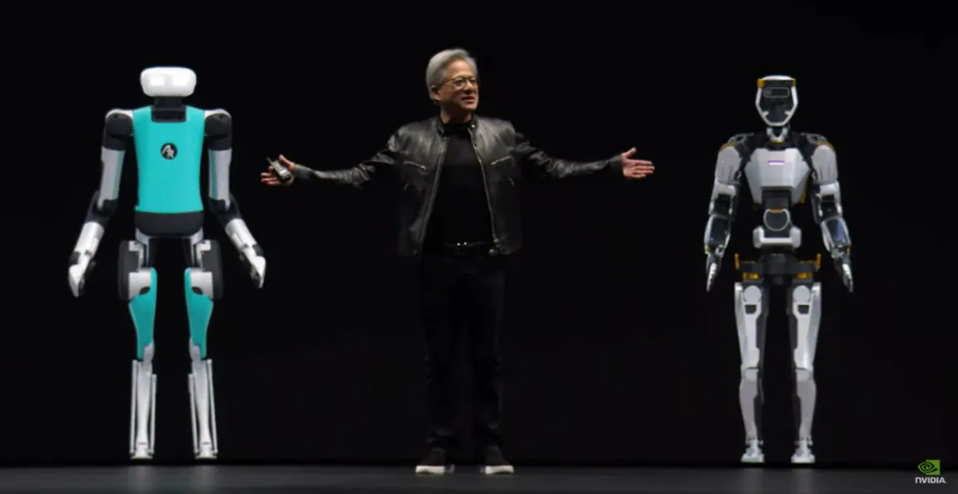

The Pioneering and Enterprise AI phases both involved AI showing and telling us things through generation. "Physical AI," the third and final stage will be markedly different in Huang's view because AI will be occupying a form and directly interacting with the world around it.

This final phase, now emerging, involves robots that take on physical tasks, from assembling structures to inspecting building facades, all while operating in environments designed for human workers. Unlike current AI applications, which largely focus on providing information or facilitating virtual interactions, Physical AI's robots can navigate complex, real-life environments and adapt to new situations in real-time.

If Huang’s vision is correct, robots powered by advanced AI will soon become ubiquitous in our homes, workplaces, and even construction sites.

The potential impact of Physical AI on the AEC industry is profound. Construction sites, often chaotic and hazardous, could be transformed by AI-powered robots capable of performing tasks with precision and safety. These robots, designed to mimic human abilities, would be particularly effective in environments where the human form factor is essential, such as navigating narrow spaces or manipulating tools designed for human hands.

The potential for AI to take on roles traditionally reserved for skilled human labor is coming. Imagine robots that can autonomously weld, paint, or assemble complex structures, reducing the risk of injury and improving efficiency on construction sites. Increasingly, this technology is able to handle the massive amounts of data required to operate in real-time, making it possible for robots to adapt to unexpected challenges on the fly.

Moreover, the ability to simulate these robots' interactions within a virtual environment will allow users to test and refine processes before deploying them in the real world. This kind of simulation will not only dramatically improve site safety, but could also revolutionize project planning, enabling more accurate timelines, cost estimates, and resource allocation.

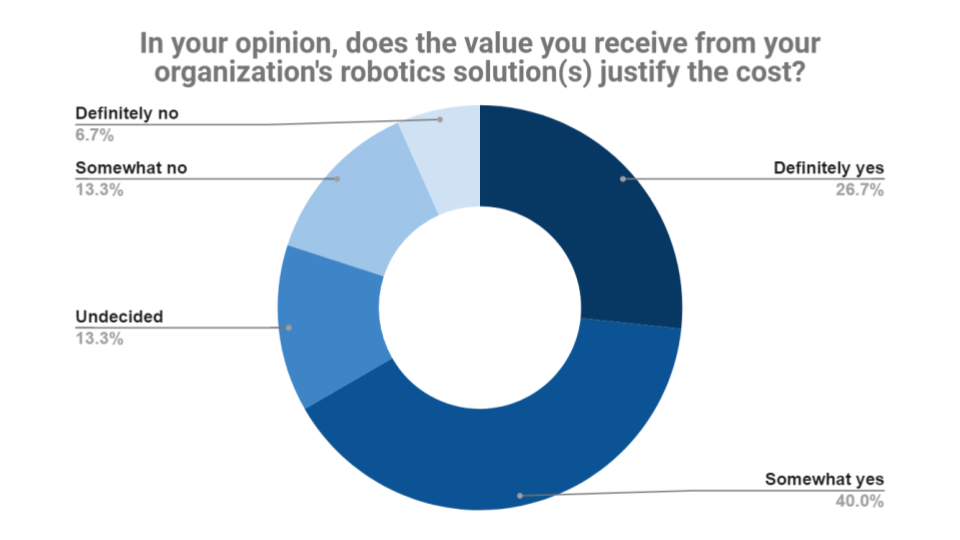

The case for construction robotics is being made across the built environment. With technological capabilities expanding, return on investment might soon follow, leading to more and more sightings of robotic solutions on site.

As Physical AI becomes more prevalent, AEC professionals must prepare for this shift. Early adopters will likely have a competitive edge, leveraging AI-powered robots to improve project outcomes and reduce labor costs. However, success will depend on the industry's willingness to embrace change and invest in the necessary infrastructure.

Already, BuiltWorlds' 2024 Tools, Equipment, and Robotics: Robotics Tech Specialty Report found that 65% of benchmark survey respondents are using a robotic solution to some extent and 66% of those respondents believe the value they receive from their robotics solutions justifies the cost to some extent.

Diving deeper into AI more specifically, BuiltWorlds' 2024 AI/ML: Tools, Equipment, and Robotics Tech Specialty Report found that 69% of identified robotics solutions are using AI in a meaningful way. This research found AI technology has been particularly effective at enabling robots to perform complex tasks.

Training programs will be essential to equip workers with the skills needed to manage and operate AI systems. Furthermore, collaboration between AI developers and AEC professionals will be crucial to ensure that these technologies meet the industry's specific needs.

Physical AI is not just a futuristic concept—it's a rapidly approaching reality. For the AEC industry, this means a fundamental transformation in how we design, build, and maintain the built environment. Huang is especially eager for this future, given that Nvidia's AI hardware provide the processing power needed to run these complex robots.

Huang's vision offers a glimpse into a future where robots are not just tools but active participants in the construction process. By embracing this change, the AEC industry can position itself at the forefront of innovation, leading the way into a new era of construction.

Interested in more applications of AI and robotics in the built world?

Check out our AI/ML Preparedness and Tools, Equipment, and Robotics Research Tracks today!

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.